We attend different fairs globally ,we have cooperated with several hundreds of clients from over 100 countries and areas

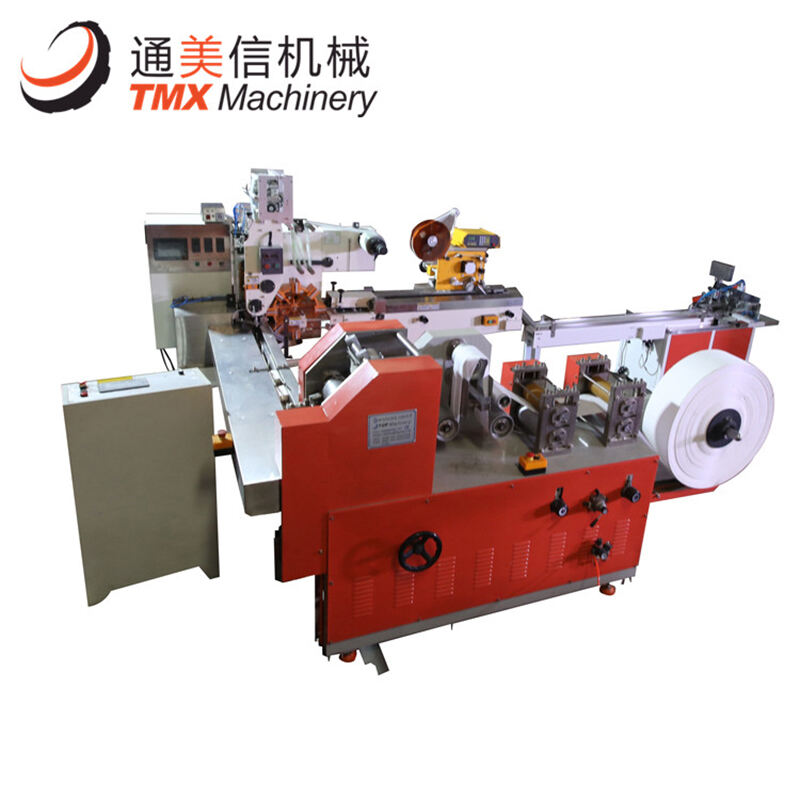

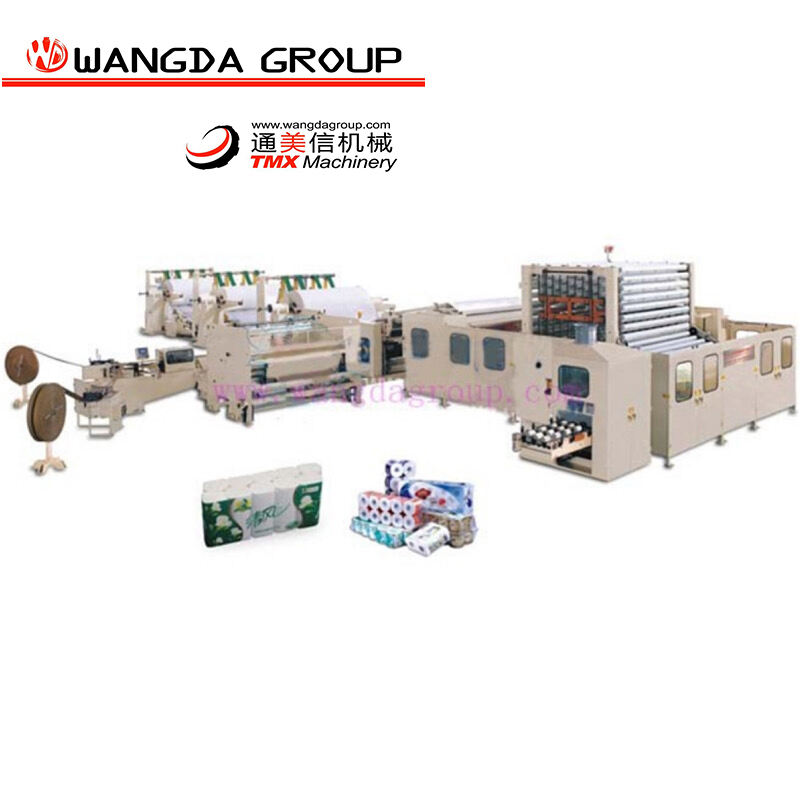

Wangda has collaborated with various customers from both the home country and Wet tissue manufacturing machine. We have worked with huge groups from GCC countries, such as Fine Hygienic from different nations, Nesto Hypermarket, Top one and two hygienic producer B and G, the Meghna Groups from Bangladesh. Outnet Group of African countries. And there are many major European brands, American brands, Latin American brands we have worked with for a great many years. We have several sample factories outside of the United States that you can visit to look at our products which are more convenient. Also you are welcome for a visit to our factory and look at our products in person. We will be happy to answer your questions at any time, and we hope to start our mutual benefit story soon.