Production Introduction:

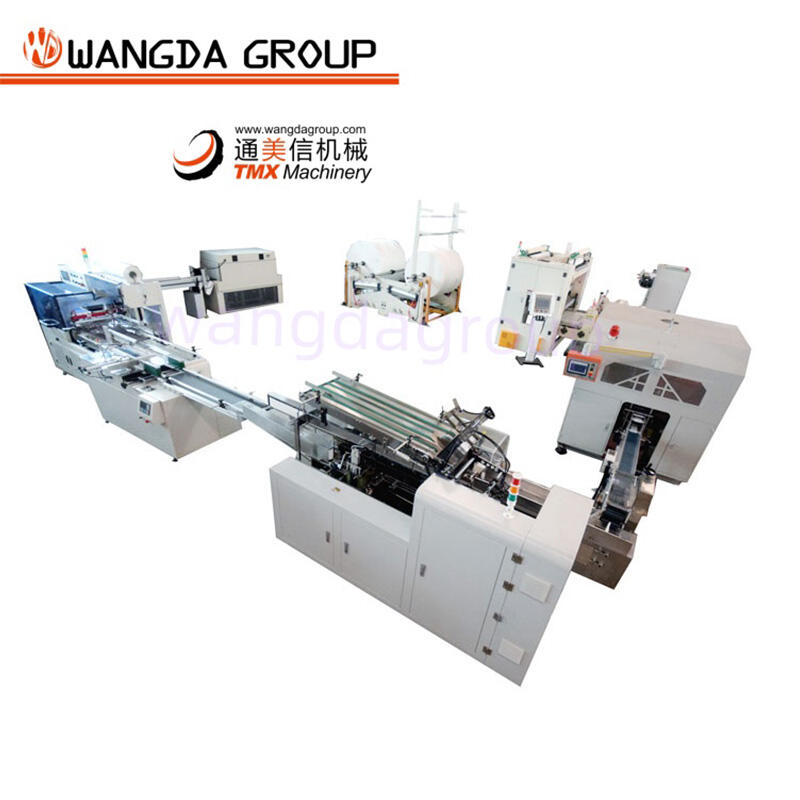

This Full Automatic Toilet Paper Production Line includes one set of Full Automatic High Speed Toilet Paper Rewinding and Perforating Machine, one set of Logs Accumulator, one set of Full Automatic Log Saw Machine, and one set of Full Automatic Toilet Roll Packing Machine for Multiple Rolls which is an ideal production line for professional manufacturer can save labors ,increase the capacity .And we have sample factory overseas.Welcome your enquiry for further information and factory visit.

Product Details:

I.WD-TP-RPM 1092-3200IV Toilet Paper Rewinding and Perforating Machine

This Toilet Paper Rewinding and Perforating Machine usually includes unwind stands which are 2-4pcs can be ordered,embossing units there are single or double or lamination units,perforating units that is the perforating distance can be ordered,rewinding units ,core storage device and the finished product diameter can be adjusted.And there are different width and different capacity of such Toilet Paper Rewinding and Perforating Machine for your choices.

Unwind stand: wallboard structure

1.Max jumbo roll width: 1350-3150mm (according to your demands model); max. diameter 1500mm, core inside dia.76mm.

2.The machine has equipped with 2 jumbo roll stands.

3.Jumbo roll stands: wallboard structure, use whole piece of thick steel plate processed by CNC and laser machine to guarantee the machine high speed stable running.

4.Through this equipment the raw paper with 1350mm-3150mm width and with 1.5m dia. can be easily sent to the raw paper stand.

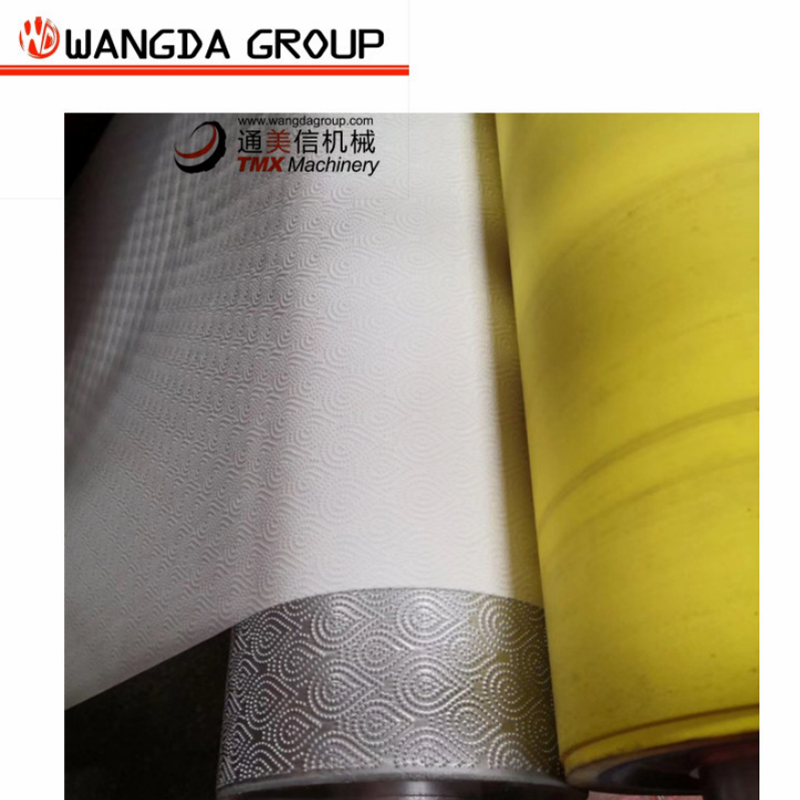

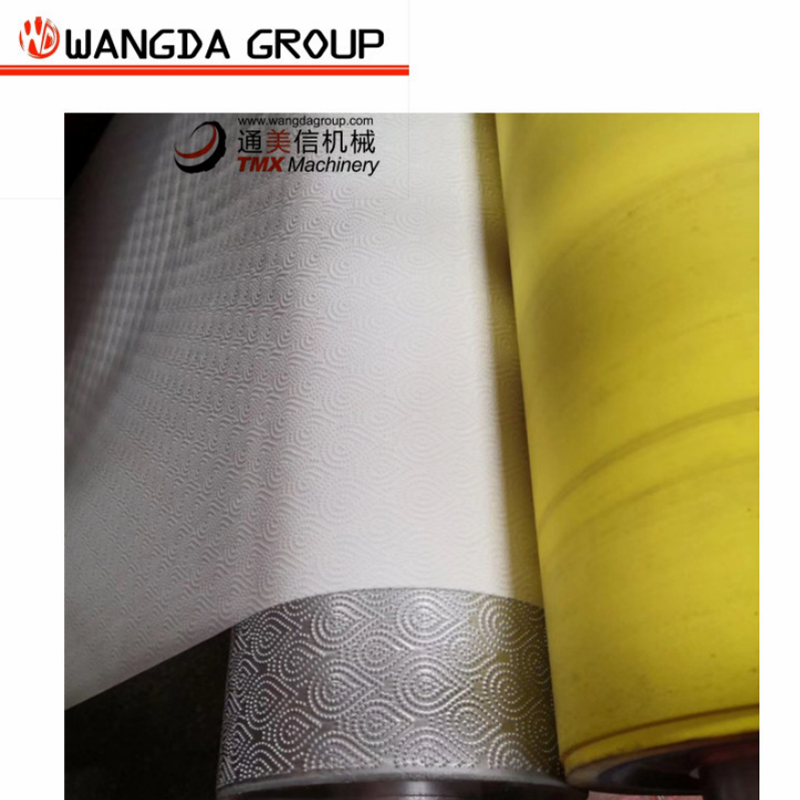

Embossing device (optional device)

1.Embossing type: Steel to Rubber (also can be steel to steel, and steel to woolen)

2.The machine can equip with single embossing device and double embossing device.The embossing effect can be fluffy or can be non-fluffy as you request. The embossing effects are obvious ,nice and beautiful.

3.Glue lamination or non-glue lamination device can be ordered also .

4.Edge embossing or mechanical sealing can be ordered also.

Perforation unit

1.Perforating: Perforating distance: adjustable,2 pieces of circular soft knives,the distance is 160-320mm (Other Size to be Specified) Perforation knife:4 knives: the distance is 80-160mm,

2.Can order servo control perforating distance adjusting.

3.Perforating control: pneumatic or servo motor

Rewind Part and Core Accumulator

1.Rewinding Technology: The finished products from earlier loosening to later tightening when rewinding, which has solved the problem of the separation phenomenon between roll paper and roll core of the finished product after long time’s storage.

2.High speed rewinding can reach the speed of 200m/min

3.Dia. of Finished Product: Can adjust

4.Dia. of Finished Product Core: ¢35-76mm(please point out)

5.Continue adding roll core alarming device.

6.Automatically changing the roll core for each toilet paper roll one by one.

II. Logs Accumulator

Main Introduction :

This log accumulators can be 100pcs,150pcs or 200pcs according to the rewinding and perforating machine speed. It can dry the tail glue and store the long logs of toilet paper and kitchen towel to balance the speed of the main toilet paper and kitchen towel rewinding and perforating machine and the afterwards log saw cutting machine for toilet paper and kitchen towel .

III.WD-TP-LSMI Full Automatic Toilet Paper Log Saw Machine

Machine Introduction:

This full auto high speed log saw machine is used to cut long toilet paper rolls and kitchen towel rolls with high efficiency and high capacity.

Main Features:

1. When the paper roll is pushed into the cutting system, it will be nipped by the clamp tool and cut after it is sent to the blade.

2. Equipped with advanced photoelectric checking system and large diameter of spiral cutter, it can auto set the length and cut precisely.

3. The cutting system is under perfect designed with auto sharpening system, while the grinding bowl can count precisely to grind the blade in time as per the cutting times.

4. The machine adopts advanced servo driving, frequency convention speed regulating. PLC control and touching screen operation. The blade grinding frequency, the cutting speed as well as the cutting length is adjustable on touch screen. Which have smoothed the pushing, cutting and sharpening.

5. Suction Device can absorb the waste produced by sharpening and discharge it out of the machine. It is helpful to make the grinding sharper and reduce of the rate of defective products.

IV. WD-TP-PM9 Full Automatic Toilet Paper Packing Machine for Multiple Rolls

Machine Introduction:

Adopting European electrostatic adherence technology, this machine is the most advanced toilet paper packaging machine in China. It is suitable for multiple rolls toilet paper packaging.

Main Features:

1. Adopting double-drive vertical sealing device, makes the vertical sealing stable, firm and neat

2. Function of automatic stop at the fixed position is available

3. PLC control makes the system reliable and easy maintenance

4. Frequency control makes the operation easy and simple

Adopting photoelectric sensor to test the eye mark, non-contact point control, two-way tracking

Technical Data of Toilet Paper Rewinding and Perforating Machine

| Model |

1092IV |

1575IV |

2000IV |

2200IV |

2800IV |

3200IV |

| Max Width of Raw Paper(mm) |

1350 |

1750 |

1950 |

2150 |

2750 |

3150 |

| Outer Dia. of Raw Paper |

¢1500mm (Other size to be specified) |

| unwinding stand |

2 Stands |

| Inner Dia. of Raw Paper Core |

3〞(76.2) (Other Size need order) |

| Data setting |

Human-machine interface(the touching screener is optional.) |

| Programming Controller |

PLC |

| Machine Speed |

180-200m/min |

| Outer Dia. of Finished Product |

90-150 mm or 90-300mm (Other Size to be Specified) |

| Dia. of Finished Product Core |

¢35-76mm please point out |

| Dia. Control of Finished Product |

Electronical / pneumatic |

| perforating |

2 pieces of circular soft knives,the distance is 160-320mm,4 knives: the distance is 80-160 mm(Other Size to be Specified) |

| Perforating distance |

Adjustable |

| Pneumatical System |

Air Compressor, minimum pressure 5kg/cm2pa(offered by customers) |

| Control Voltage |

Regulated power 380V 50Hz (for your reference ,need order) |

| Main Machine Structure |

Wallboard type |

| Mainframe Transmission |

Stepless gear-box |

| Main Transmission |

conversion adjusting 5.5-22kw |

| Optional function |

| Perforating control |

Pneumatic |

| Embossing |

Single Embossing, Double Embossing, Steel to Steel Embossing ,Pneumatic Embossing,Non-glue Lamination (To be Ordered) |

| Edge Embossing |

Independent Pneumatic |

| Gluing and Laminating |

kitchen paper towels: Gluing form point to point or point to the whole surface of the paper |

| |

Color glue tissue roll |

Technical Data of Log Accumulator

| Log length |

1800-3200mm, can be ordered |

| Log outer diameter |

90-150mm, can be ordered |

| Workable roll storage |

100-200pcs, can be ordered |

| Storing Speed |

25 logs/min |

| Installed power |

AC motor 2HP:2 sets |

Technical Data of Full Automatic Toilet Paper Log Saw Machine

| Paper Roll Length: |

1300~3200mm |

| |

Outer Dia.: 90-150mm(unless specified request, we generally supply the clamp according to the standard of 110±5mm) |

| Specification of the Finished Products |

Cutting Length: 50-300mm( adjustable) |

| |

Edge Length: 25-30mm |

| Design Speed |

120-150cuts/min |

| Stable cutting speed |

100-120 cuts/min |

| Pushing drive control |

servo motor drive, |

| Knife sharpening |

Pneumatic grinding wheel, time and rate can be controlled on panel, it can grinding through automatic process |

| Outer Dia. of Circular Knife |

610mm |

| Power |

8KW |

| Packing Size |

It will be different according to the final allocation |

| Weight |

2500-3000kg |

Technology Parameters of Full Automatic Toilet Paper Packing Machine for Multiple Rolls

1.Packing spec: 8, 12,16,18,24,32 toilet paper rolls and 3, 6 kitchen towel rolls.

2.Design speed: 20-25packs/min Stable packing speed: about 16-20packs/min depends on the packing quantity of rolls .

3.Packing material: PE pre-made bags.

4.Air pressure:0.5Mpa-0.7Mpa (provide by the customer).

5.Power supply: 380V, 50HZ 3phases.

6.Total machine power:about 9.5kw

7.Machine weight: about1500kg

8.Machine size: about14.13*1.2*1.73m ( including connecting unit)