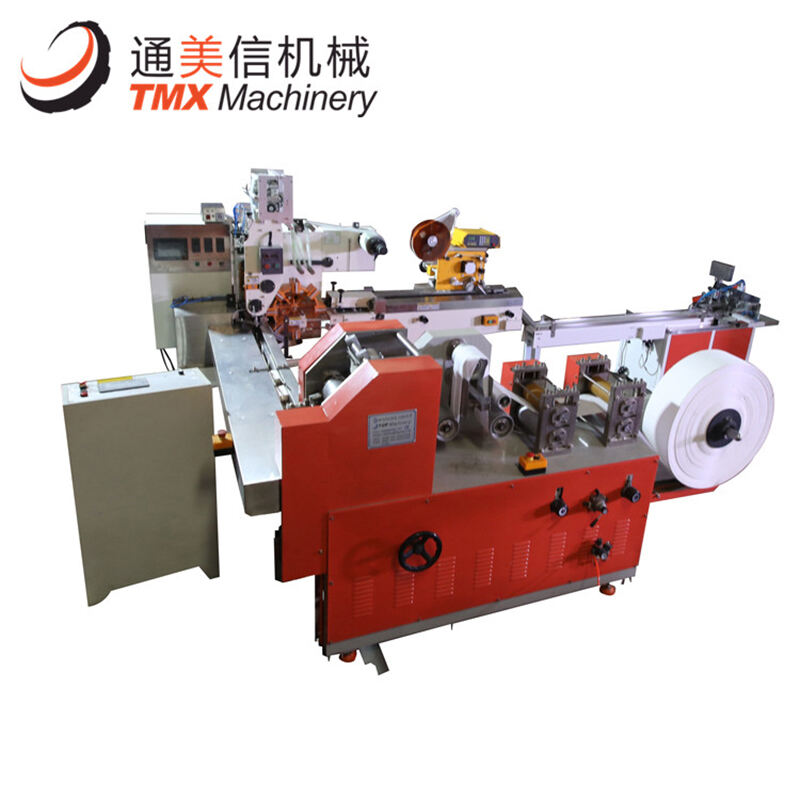

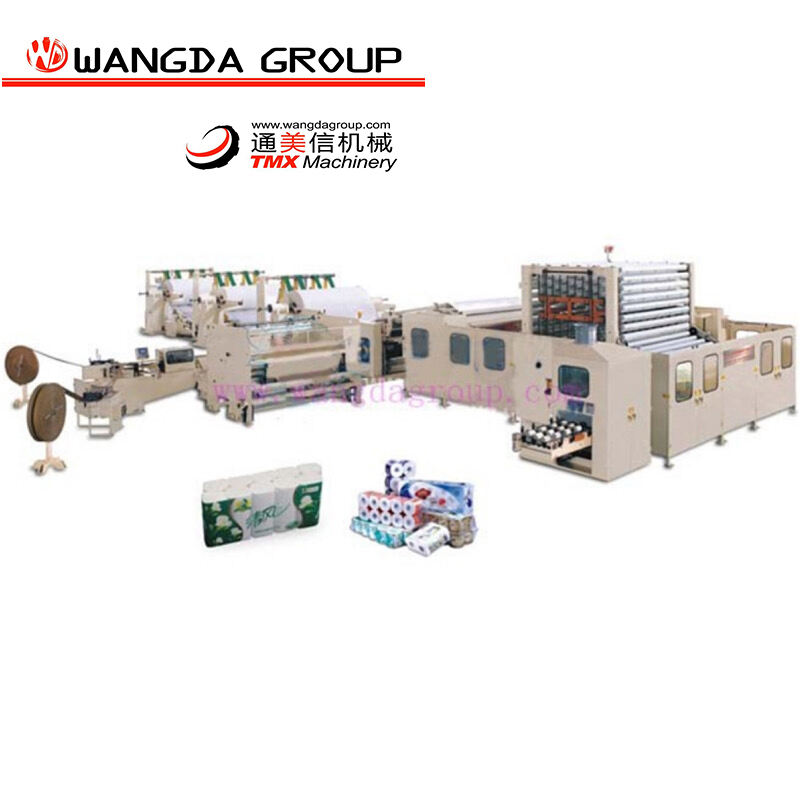

One of the most professional and highest quality factory for hygienic products machines in the whole world.

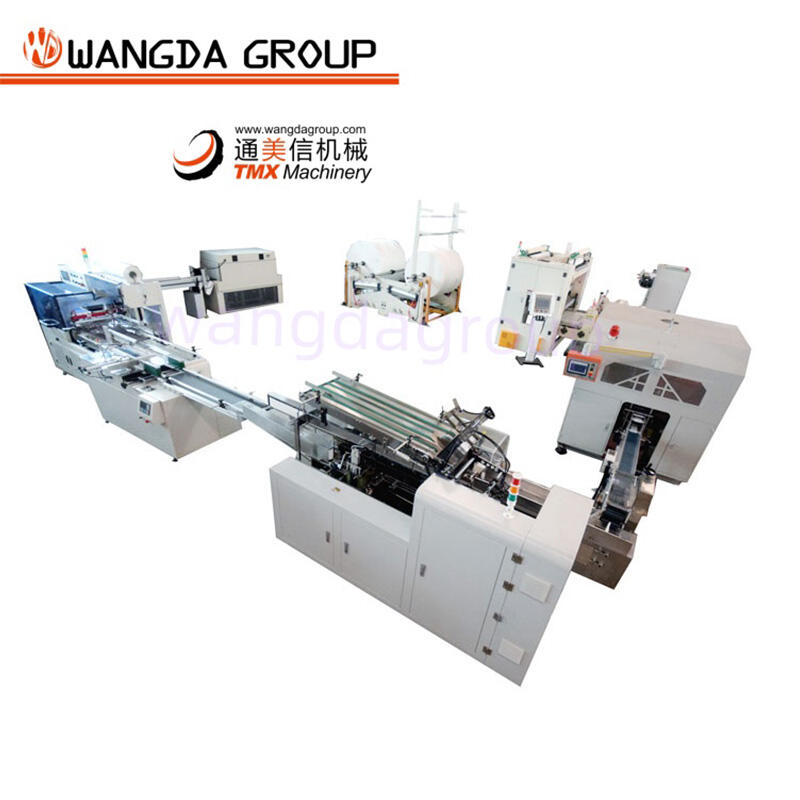

Wangda has more than 20 years experience in the production of various tissue machines. We take great care of the machines' functions and the quality, and additionally, we provide after-sales and pre-sales services. We've sold machines to over 100 countries, which has resulted in many repeat orders and good reviews from our clients. Wangda has its own R and D departments. Our machines are based on advanced Germany, Japan and Italian technology and is updated day by day. Our machines has passed Tissue paper manufacturing machine, CE, BV and many more certifications. What we supply is not only machines. What we supply is turnkey projects from A-Z. can accept customized requests for these tissue machines.