Production Introduction:

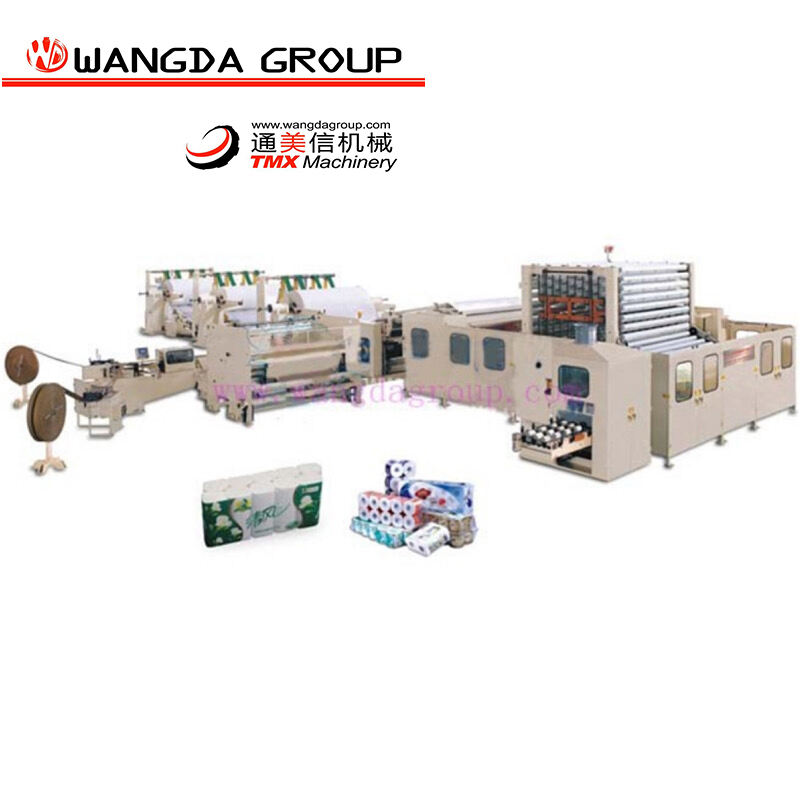

This Full Automatic Non -stop Toilet Tissue/Kitchen Towel Production Line includes one set of Non stop Full Automatic High Speed Toilet Paper Rewinding and Perforating Machine,one set of log accumulators,one set of Full Automatic Log Saw Machine, one set of Full Automatic Toilet Roll Packing Machine for Single Roll,one set of Full Automatic Toilet Roll Packing Machine for Multiple Rolls and one set of Online Roll Core Machine.This production line can order different kinds of speed from 250-500m/min.This production line speed is fast and capacity is big ,it is good line for professional toilet tissue and kitchen towel manufacturer.

Product Details:

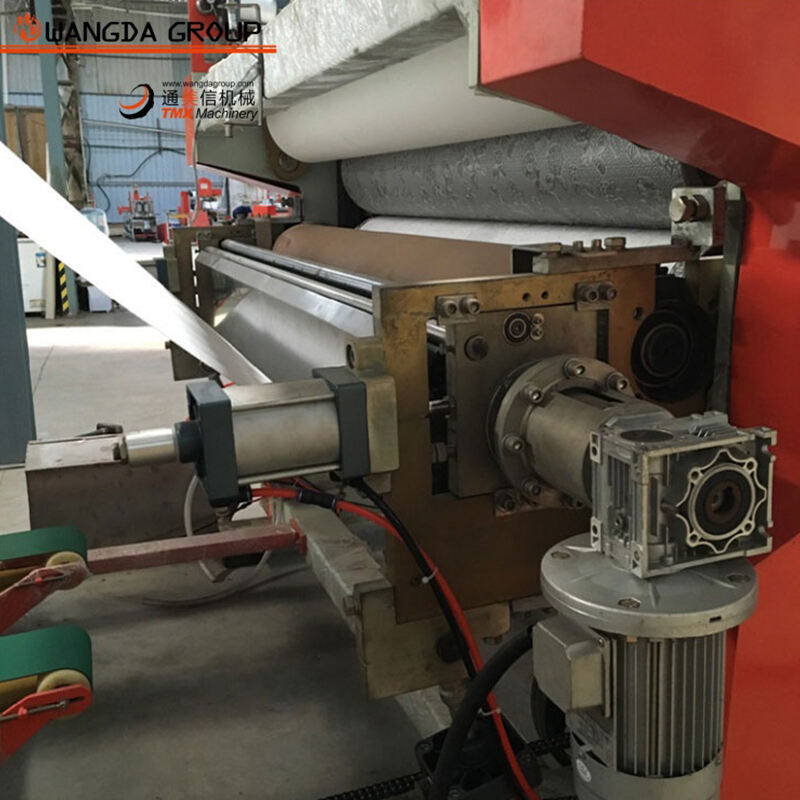

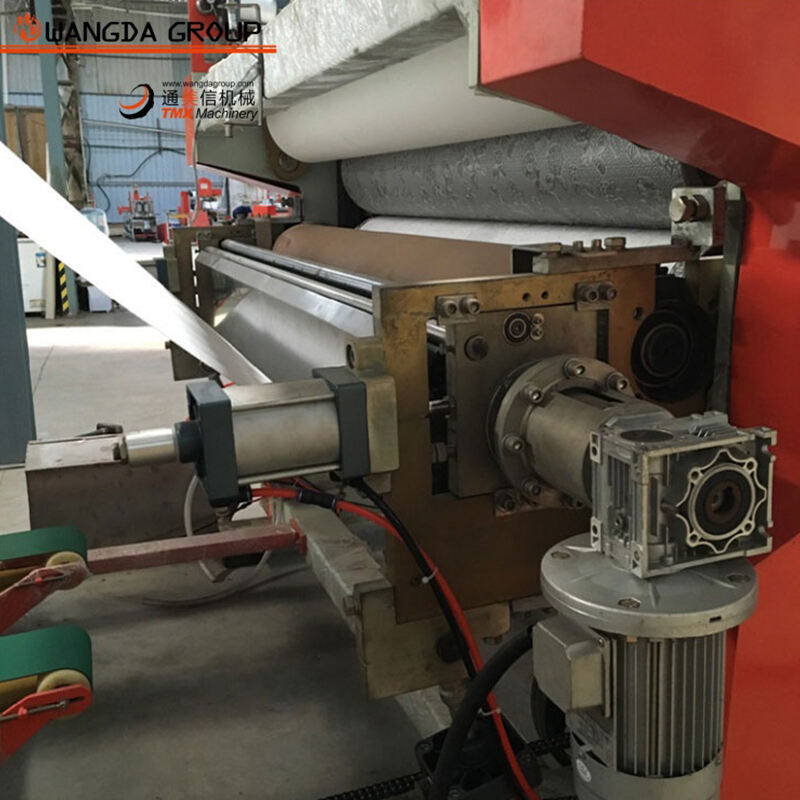

I WD-TP-RPM 1092-3200IVNS Non stop Full Auto High Speed Toilet Paper Rewinding and Perforating Machine

I.Machine Introduction

The nonstop rewinder is for core re-winder production line with advanced manufacturing concept new machine,with PLC, touch screen for operation, Servo motor,independent inverter drive, sensor detecting for auto detecting of every movement on the production line to make the line to be best performance, our machines are the best choice for many tissue paper companies.

II.Main Specification

| Design speed |

with core: 300meter/min |

| Out-feed logs: 15 logs/min |

| Production speed |

With core: 250meter/min With lamination: 200m/min |

| Out-feed logs: 14 logs/min |

| Valid roller width |

for max jumbo roll width 2950mm |

| Estimated daily production |

with core production capacity is about 10 tons/day (various according to different specs) |

| Applied jumbo roll |

Straw jumbo roll, virgin pulp jumbo roll, Sugarcane pulp paper, bamboo pulp paper |

| Jumbo roll spec |

13g/m²-24g/m² |

| 1.5meter back stand |

4team without axis |

| Main machine |

1set, including edge embowering, sealing part |

| Sealing machine |

1 set |

| Accumulator |

Optional |

| Single embosser |

Optional |

| Glue laminated part |

Optional |

Glue laminated part

II.WD-TP-LSMI Full Automatic Toilet Paper Log Saw Machine

I.Machine introduction

This full auto high speed log saw machine is used to cut long toilet paper rolls and kitchen towel rolls with high efficiency and high capacity.

II.Main Features

1. When the paper roll is pushed into the cutting system, it will be nipped by the clamp tool and cut after it is sent to the blade.

2. Equipped with advanced photoelectric checking system and large diameter of spiral cutter, it can auto set the length and cut precisely.

3. The cutting system is under perfect designing with auto sharpening system, while the grinding bowl can count precisely to grind the blade in time as per the cutting times.

4. The machine adopts advanced servo driving, frequency convention speed regulating. PLC control and touching screen operation. The blade grinding frequency, the cutting speed as well as the cutting length is adjustable on PLC screen. Which have smoothed the pushing, cutting and sharpening.

5. Equipped with pneumatic brake function, can prolong the service life of motor and make braking perfect.

6. Suction Device can absorb the waste produced by sharpening and discharge it out of the machine. It is helpful to make the grinding sharper and reduce of the rate of defective products

III.Machine parts

III WD-TP-RCM High Speed Roll core machine

I.Machine introduction

This Roll core machine is used to produce roll cores for toilet paper rolls and kitchen towel rolls.

II.Main Features

1. This machine is to produce the paper core, which is advanced in design and convenient in operation.

2. Automatically withdraw knife or insert knife to cut pipe without stopping machine.

3. The molding of products is hard and straight.

4. The composed parts are of high rigidity, equipment is stable without shaking when rolling core.

III.Finished product

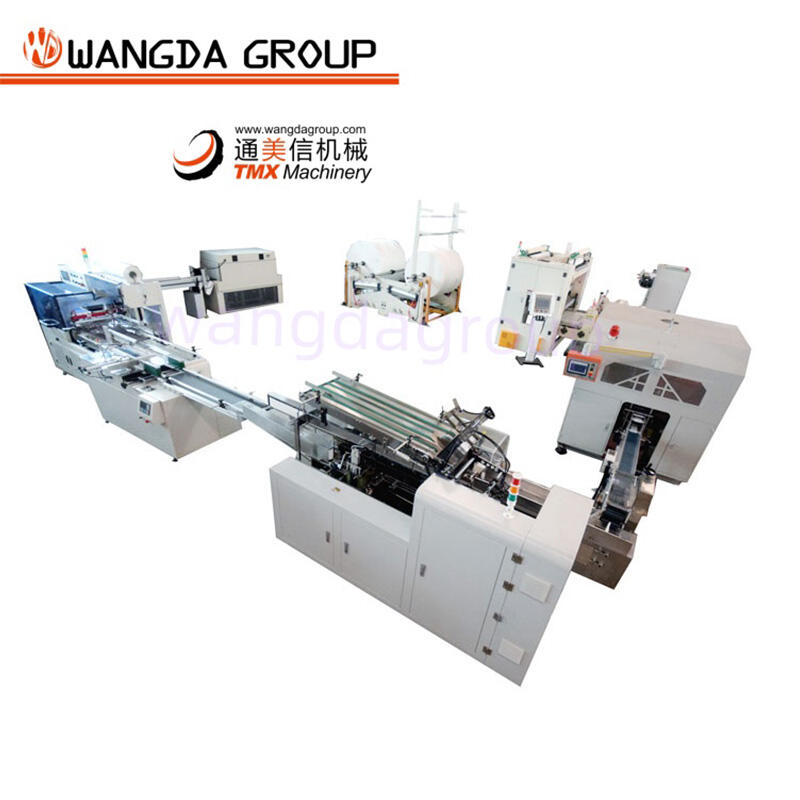

IV. WD-TP-PM1 Full Auto SingleToilet Roll Packing Machine

I.Machine introduction

This Single toilet roll packing machine is used to pack single package for toilet paper roll and kitchen towel roll.

II.Main Features

1.Machine end-sealing and film-moving action are controlled by servo motor which guarantee the quick speed and accuracy;

2.Machine adopts high speed PLC, HMI, SERVO MOTOR, TEMPERATURE MODULE to complete the running control system. And the machine program will speed changes according to the front feeding situation automatically.

3.Super big HMI and parameter set and easy to change different size. Some main area has the calculate, such as the film location;

4.End-seal is controlled by a separate module, which guarantee a best seal. And you can choose hot seal or not seal as your like;

5.The cutter will reset after cutting the material;

6.Special film supporting structure to make the film changing easy;

7.Easy to change the former to suit 90mm-120mm diameter paper;

8.Mid-seal adopts the transient heating type and when machine stops, it does not damage the film which guarantee the product percent of pass;

9.In the letter before two on unheated rubber film feeding wheel and tighten packing film device, to press paper ball for conveying products, which can also adjusted by hand to suit different size;

10.Machine main conveying system adopts the synchronous belt system;

11.Film print area location is controlled by sensor. And it can change the location in the HMI.

12.It can also change the end-seal location in the HMI;

13.Conveying characteristic

① Automatically connect with the main machine conveyor;

② It adopts the suitable material;

③ Tidying and pushing adopts separated servo driver control;

④ Empty bags and no running function to escape the waste of film;

⑤ Automatically alarm when paper stands;

⑥ Easy to adjust for different size paper;

III.Machine parts

V.WD-TP-PM9E Full Auto Multiple toilet rolls packing machine

I.Machine Introduction

This Multiple toilet rolls packing machine is used to pack multiple packages for toilet paper rolls and kitchen towel rolls.

II.Main Features

1.Running Control: bag pushing, bag conveying, bag loading and toilet paper conveying use the servo system control and high sensitivity sensor tracing;

2.Operation: Touch screen operation and human-machine show;

3.Emergency stop and safety door;

4.Automatically alarming system and it shows alarm in the touch screen;

5.Pre-made bag giving type, vacuum air conveying and no bag, no pushing function;

6.Turning system: Make the toilet paper standing;

7.Tidying system: different packing type and packing pieces;

III.Finished product

IV.Machine parts

I.Technical Parameter of Non stop Full Auto High Speed Toilet Paper Rewinding and Perforating Machine

Main machine 1set/line

| Max jumbo roll width |

2950mm |

| Re-winder type |

continuous running, jumbo roll offloading, jumbo roll changing, the machine no need to stop. |

| Roll break type |

back scrub board cut off tissue paper |

| Machine structure |

wallboard type |

| Finished roll diameter |

¢80mm-¢130mm,with core :¢80mm-¢130mm |

| Re-winder length |

pieces is set on the screen |

| Jumbo roll loose function |

the jumbo roll will be spread on the horizontal direction through the arc roller, the arc roller can be rotated |

| Finished rolls core tube out-diameter |

¢35~¢50mm (tube diameter needed be fixed by customer) |

| Machine jog function |

yes |

| Edge embowering type |

on the inter-folder head part is amounting with edge embosser unit, the whole part is with air pocket to press to realize the embosser, with good quality air pocket, the embosser is good quality and even. |

| Hope punch device(114mm,and 230mm+-3mm) |

1 piece of rotary cutter roller with 4 blades and 1 piece of fixed cutter roller |

| Hole punch cutter load and off load is controlled by cylinder |

| Hole punch distance adjustable: controlled by inverter |

| Hole punch distance |

adjust on the HMI |

| Hole punch distance offset |

±2mm |

| Hole punch distance ratio |

6mm:1mm & 3mm:1 (can order) |

| Hole punch unit angle adjustment |

manual |

| Tube automatically input |

AC motor intermittent motion drive the pusher chain to send the core tubes, servo motor control the core tubes into the re-winder area |

| Tube glue adding type |

with glue disk inside pushing board cooperated with spring press down to load the glue intermittently |

| Jumbo roll threading |

manual |

| Drive type |

independent motor control, servo motor, timing belt, and flat belt transmission |

| Embosser roller |

timing belt transmission, flat belt transmission |

| Ride roller control method |

timing belt, servo motor |

| Down re-winder roller control |

servo motor |

| S shape jumbo roll threading |

before hole punching, with S shape pull roller,can adjust the tape core pulley belt to adjust the hole punching and re-winder area tension |

| Paper break detect |

with sensor detecting for the breaking |

| Power |

with tube core tissue rolls: 27 kw |

| Lowest air pressure |

0.6Mpa |

| Air consumption |

about 5m³/hour |

| Machine weight |

about 7tons |

| Dynamic load coefficient |

1.2 |

| Guard |

main transmission part is protected by guards. |

III.Technical Data of Full Automatic Toilet Paper Log Saw Machine

| Paper Roll Length |

1300-3200mm |

| Outer Dia.: 100-110mm(unless specified request, we generally supply the clamp according to the standard of 110±5mm) |

| Specification of the Finished Products |

Cutting Length: 50-300mm |

| Edge Length: 25-30mm |

| Design Speed |

120-150cut/min |

| Stable cutting speed |

100-120 cut/ min |

| Pushing drive control |

servo motor drive |

| Knife sharpening |

Pneumatic grinding wheel, time and rate can be controlled on panel, it can grinding through automatic process |

| Outer Dia. of Circular Knife |

610mm |

| Power |

10KW |

| Packing Size |

It will be different according to the final allocation |

| Weight |

2500-3000kg |

III.Technical Parameter of High Speed Roll core machine

1. Production Speed: 30-40 m/min

2. Specification of Roll Core: core diameter: 50-55mm (2~6 ply), length: Adjustable

3. Specification of Jumbo Roll: 300-400 gsm, width 50~90 mm

4. Machine Power: 3Kw (380V 50Hz) (For your reference, it depends on the power situation in your place)

5. Overall Size of Equipment (L×W×H m):3.5×1×1.6 m

6. Weight of Equipment: 1.5T.

IV.Technical Data of Full Auto Single Toilet Roll Packing Machine

| Model |

WD-TP-PM1 |

| Diameter |

Toilet roll: dia100-115mm, length90-100mm Kitchen towel: dia120-125mm, length230mm(need confirm) |

| Length |

| Max film dia |

φ400 mm |

| Max film width |

420mm |

| Film thickness |

0.018mm-0.03mm |

| Film material |

SPP,CPP |

| Packing speed |

120-180 pieces/min for toilet roll (code distance≤270mm) 60-90pcs/min for towel roll |

| Motor power |

1.5 KW(film moving motor) 1KW(end-seal motor) 1KW(pusher motor) 0.75 KW + 0.75 KW (tidy and pushing motor) |

| Main machine heating power |

5KW |

| Side-ironing heating power |

3.6KW |

| General power |

14.5KW |

| Capacity |

97% |

| Print bias |

≤3mm |

| Machine running power |

≥80% |

| Machine weight |

2200(kg) |

| Outer dimension |

(L)4330mm*(W)3450mm*(H)1700(mm) |

| Power supply |

3 phase 4 line 380V 50HZ,control voltage DC24V。 |

| Compress air consumption |

6kg/cm2 0.25m3/min |

| Machine noise |

≤75(db) |

| Model |

WD-TP-PM1 |

| Diameter |

Toilet roll: dia100-115mm, length90-100mm Kitchen towel: dia120-125mm, length230mm(need confirm) |

| Length |

| Max film dia |

φ400 mm |

| Max film width |

420mm |

| Film thickness |

0.018mm-0.03mm |

| Film material |

SPP,CPP |

| Other speed of packing machine |

Other types of packing way and speed of machines can be ordered. |

V.Technical Data of Multiple Rolls of Toilet Roll Packing Machine

| Model |

WD-TP-PM8E |

| Average Speed |

18-22bags/min |

| Single toilet paper size |

dia:100-115mm, length:90-100mm |

| Packing type |

4 pieces,6 pieces,8 pieces,10 pieces,12 pieces |

| Bag size(L×W×H) |

(450-875mm)×(180-260)mm×(90-130)mm |

| Bag material |

PE Pre-made bag |

| Packing film thickness |

45μm |

| Pre-made bag stock |

2 bag stocks, automatically change and every stock capacity is 400 pieces bag |

| Machine size |

3000×1750×1900mm(L×W×H, do not include the tidying line and outlet line) |

| Whole power |

14Kw, Heating power 0.8 Kw |

| Power supply |

380V 50HZ |

| Air consuming |

0.5-0.7Mpa |

| Air usage |

30L/min |

| Weight |

Around 3000kg |

| Noise |

≤80bd |