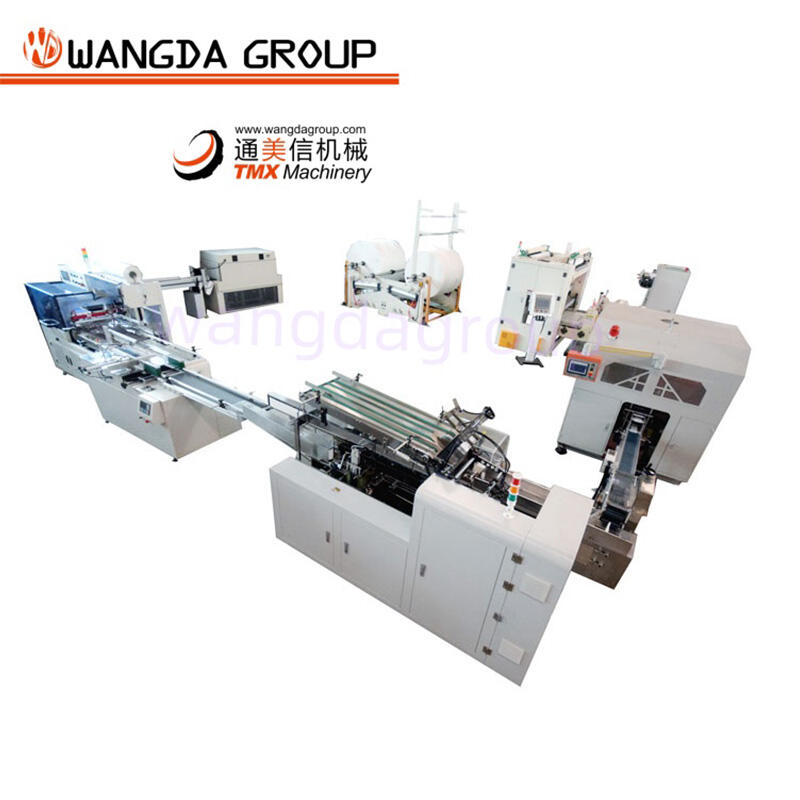

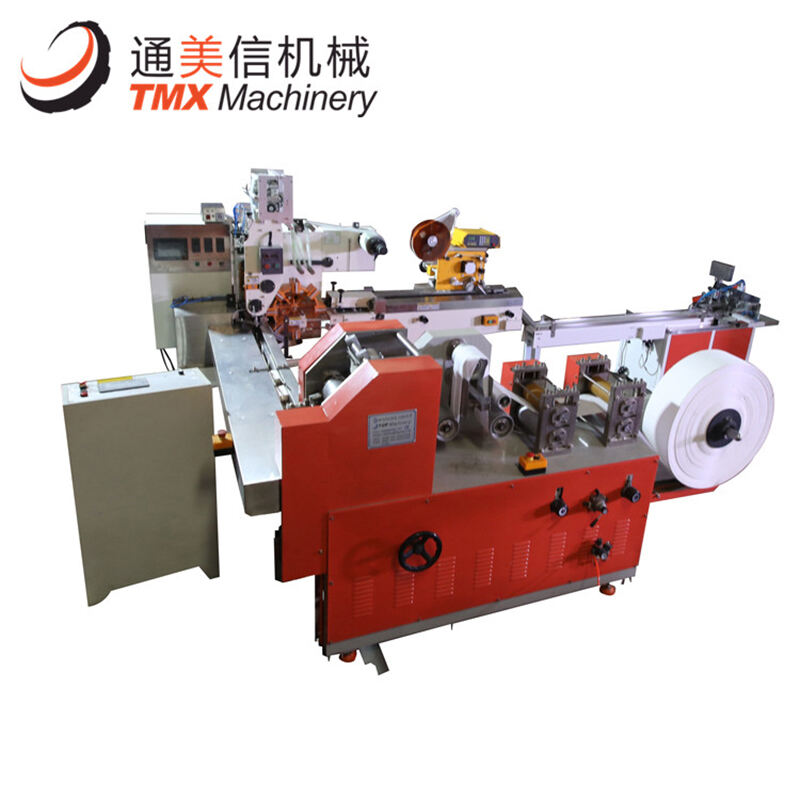

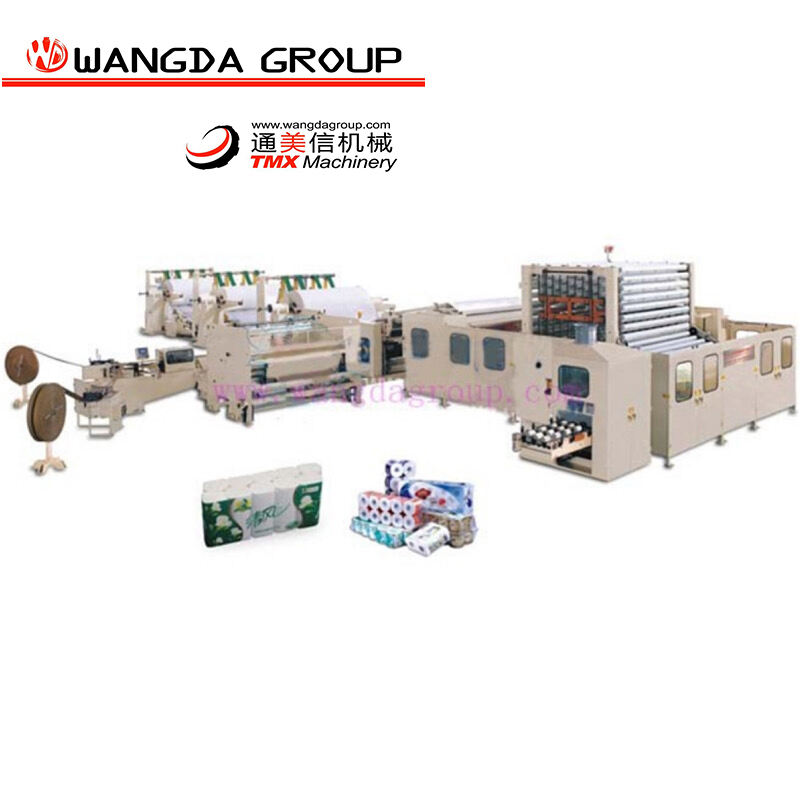

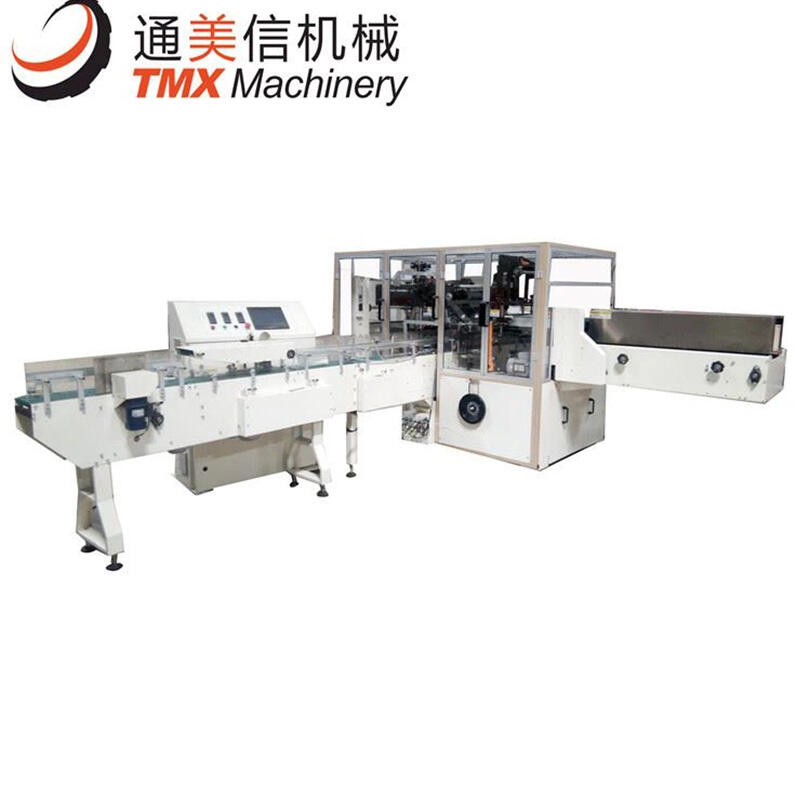

We can provide all types of tissue machines and related packing machines and raw material all turnkey project.

Toilet paper manufacturing equipment manufactures toilet paper machines, toilet paper cutting machines kitchen towel machines, kitchen towel cutting machines, kitchen towel packing equipment, facial tissue machines facial tissue cutting machines, facial tissue packing machines, box drawing facial tissue machine, nylon bag facial tissue machines, maxi roll rewinding machines, napkin paper machines serving machine, napkin packing machines, pocket tissue machines, pockets tissue packing machines, wet wipe folding as well as packing machines, and the list goes on. We offer all the materials for these hygienic products.