The Advantages of Tissue Paper Automatic Machines

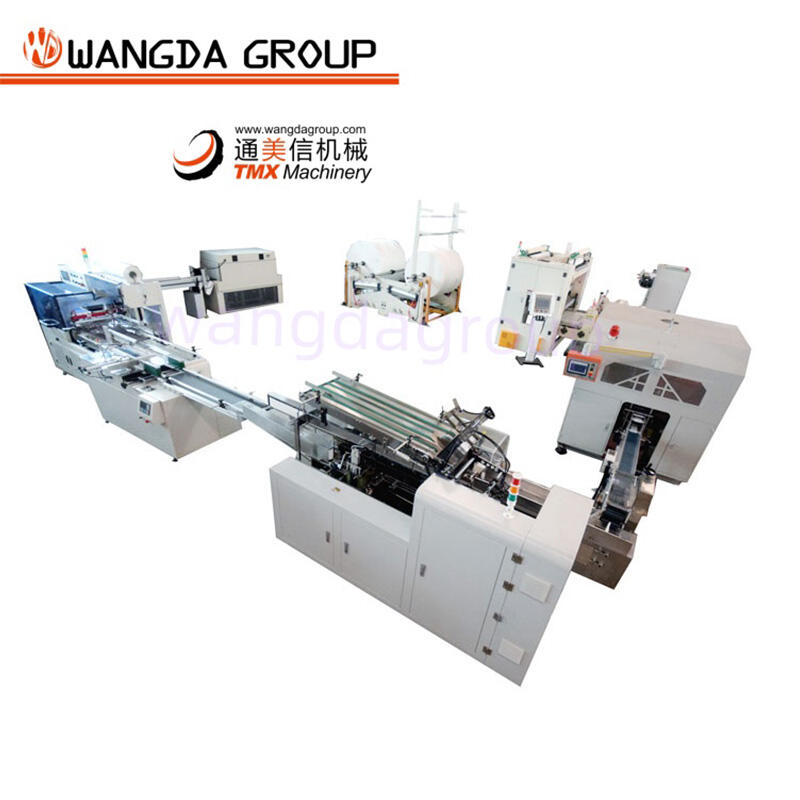

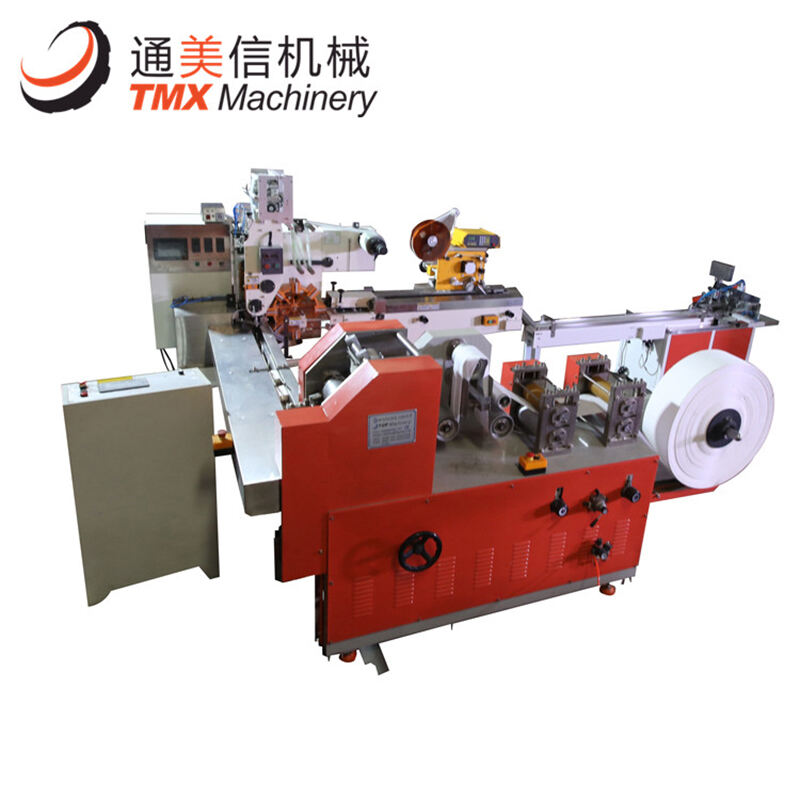

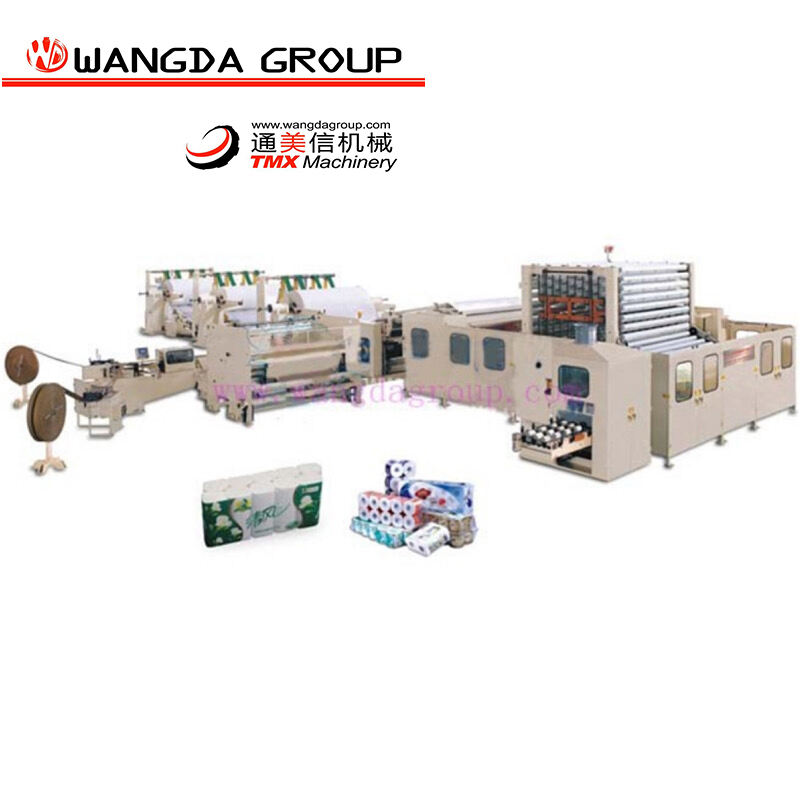

These tissues paper automatic machines truly are a dome for manufacturers therefore many things about them, just like the napkin folder manufacturer built by Wangda Industrial. The first one is, they are very fast and can generate more tissue papers in a way less time. If tissue paper is needed, then it can be produced and shipped in short order. Then, these are business devices that can almost operate independently and therefore do not require much human input on the way. Secondly, they create every single piece of this tissue paper of the same quality. When consumers purchase tissue paper, they are expecting softness and strength every day. Fourth, these machines can save a lot of money for tissue paper manufacturing companies which they could use in other parts of the business. Finally, they are good for the environment because they will help to reduce waste and reduce our depletion of resources by enabling our manufacture processes to be more efficient.