We provide professional ,experienced ,punctual presale and after-sales service for all your enquiries.

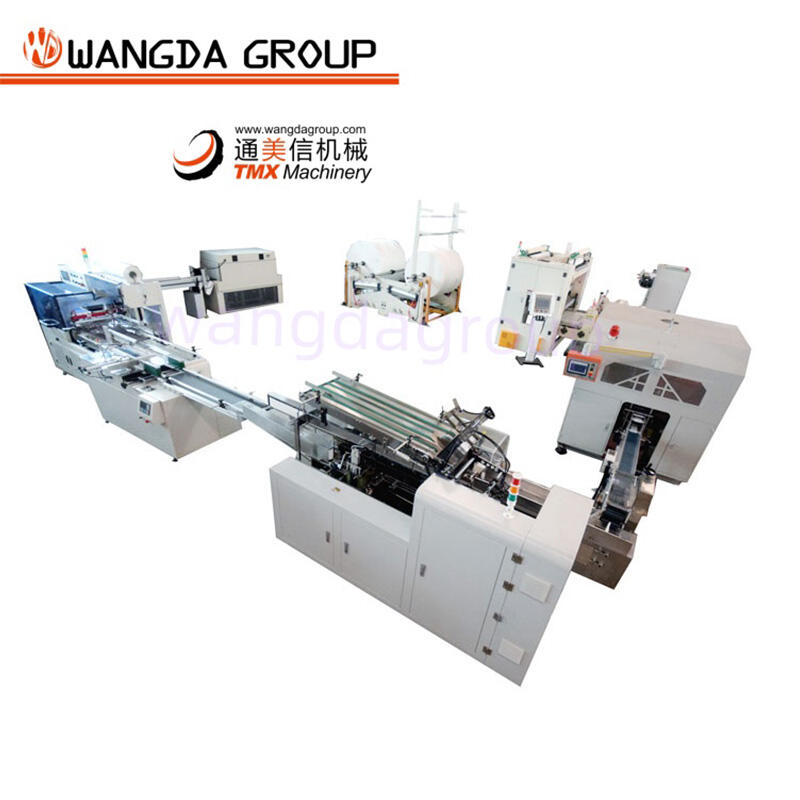

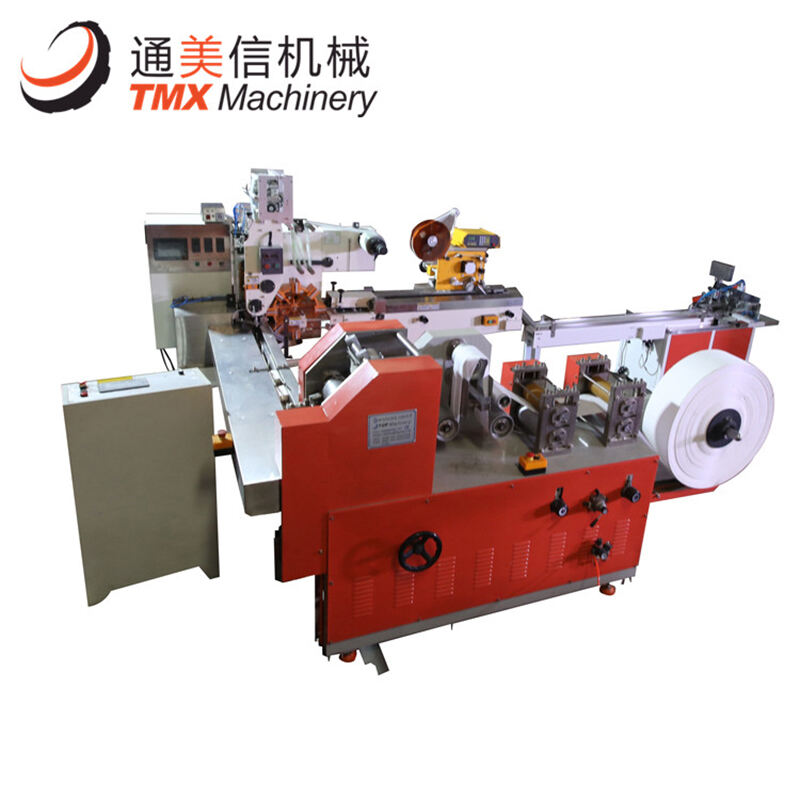

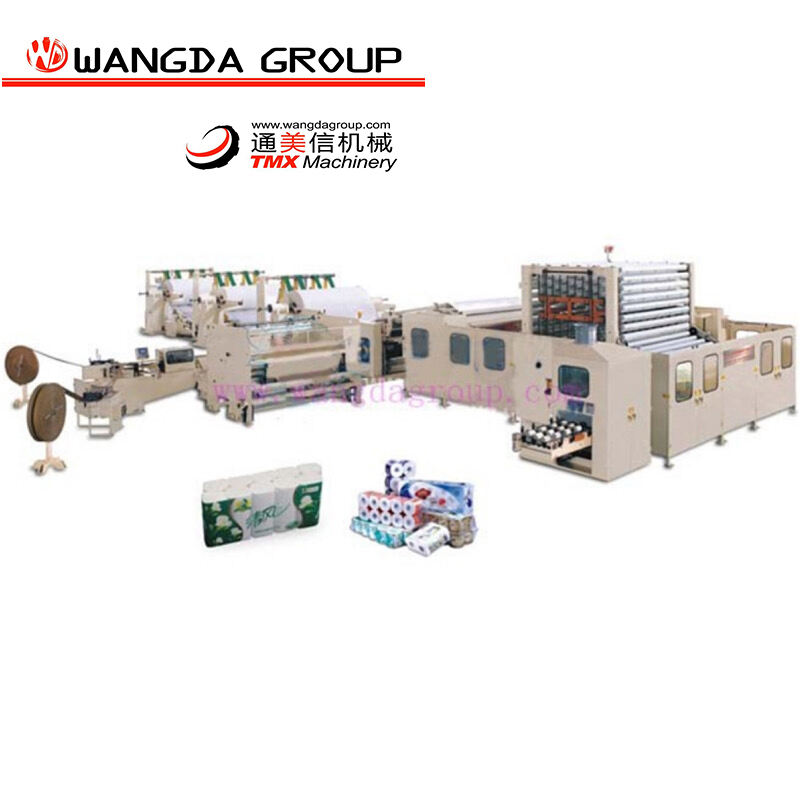

Wangda has a very experienced and experienced sales team and after-sales department, with 80% of the team have been working for over 10 years in our company in the hygiene-conscious product industry. Our team members have a lot of experience working on daily paper tissue machines, associated packing machines, and other hygienic product machines We are experts in a range of expertise in this field, we consider what our customers wants, we worry about what they are concerned about. We do Machines used to make toilet paper only sell machines to our customers, but we help our customers earn money through this hygienic product business by providing life-long after-sale services to our customers promptly.