The Journey of Toilet Paper Manufacturing Machines

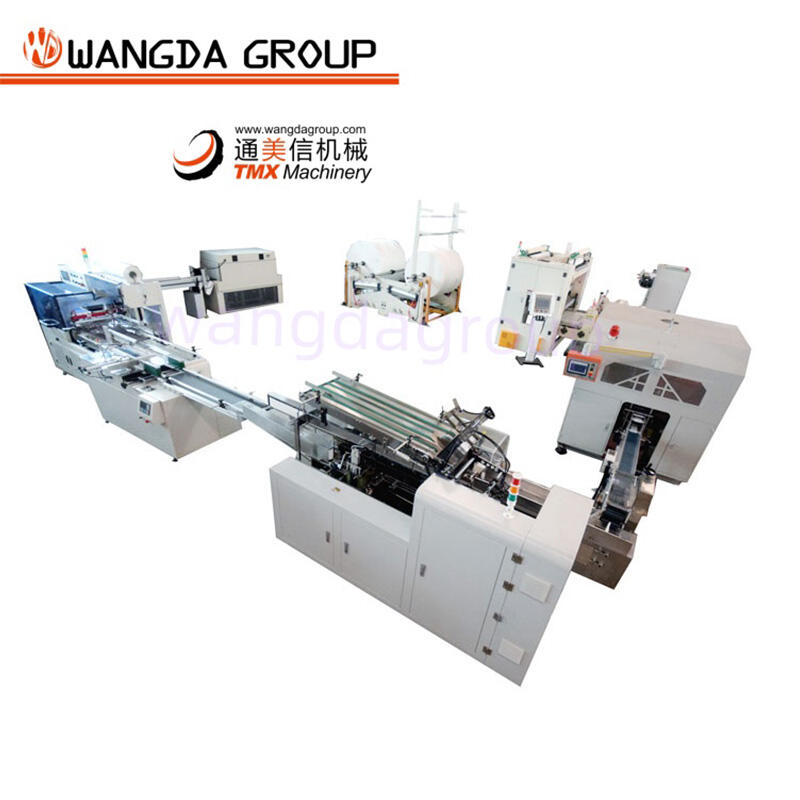

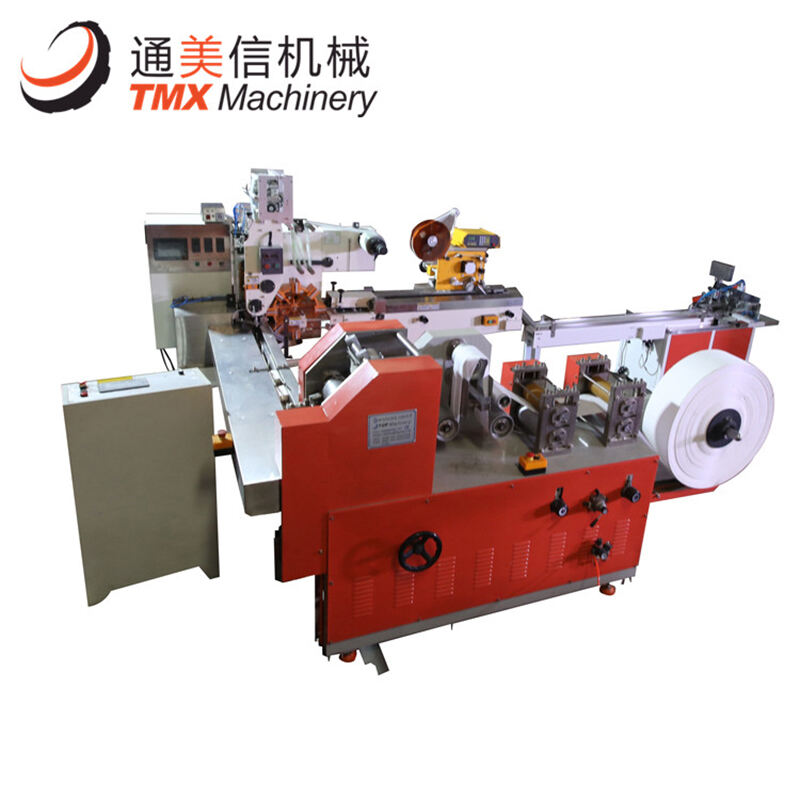

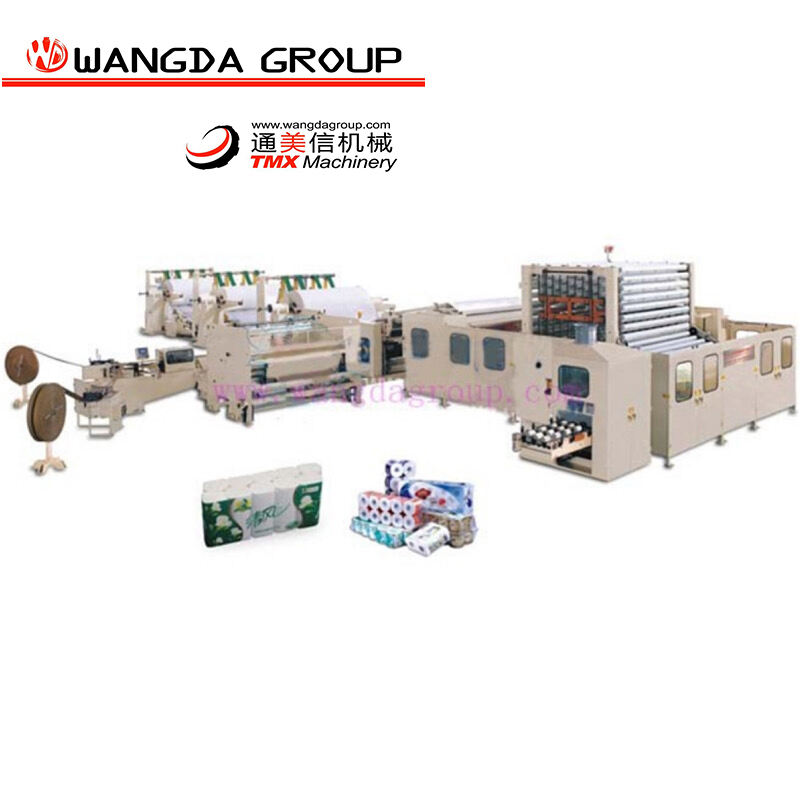

There are many critical steps involved when the spools of paper arrive at the machines. Machines inject water, press the fiber together to flatten it on a conveyor belt and then heat the mat of paper into its final shape. This is how a paper transforms from an inflexible sheet to the soft and silky. The paper is then dispensed into smaller rolls that are wrapped in plastic and boxed, to be sent off to the stores. My instinct is to buy it, so that we have a bunch whenever the time comes

Toilet paper making machines are AMAZING! They use a specialized technology to transform the wood pulp into some of the softest and most absorbent toilet paper rolls available. And that, my friends, is something pretty cool in action — to see how all those machines are working together just so I have a spoon on which to eat cereal every morning.