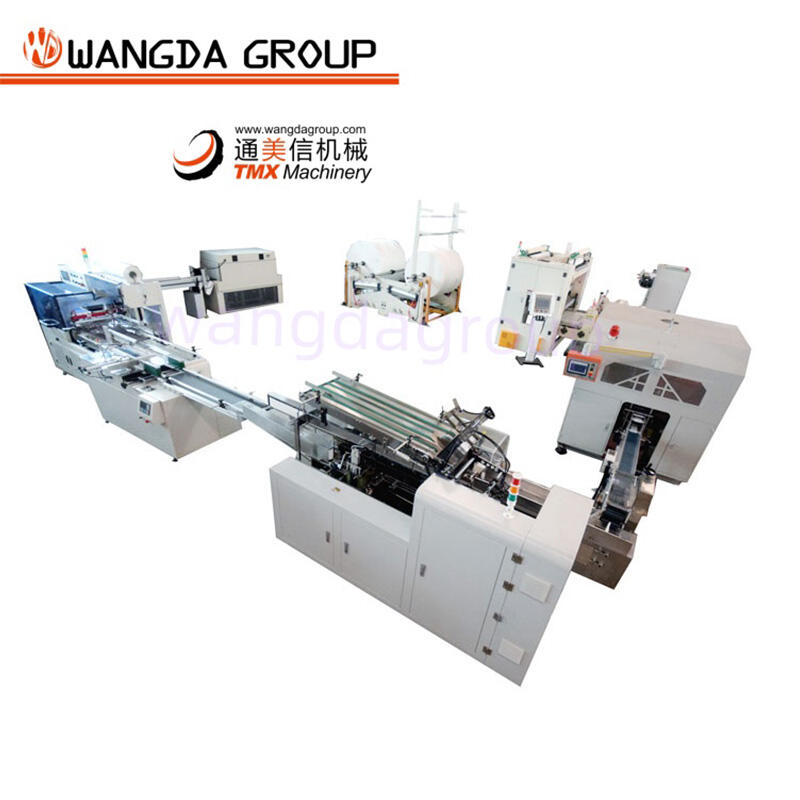

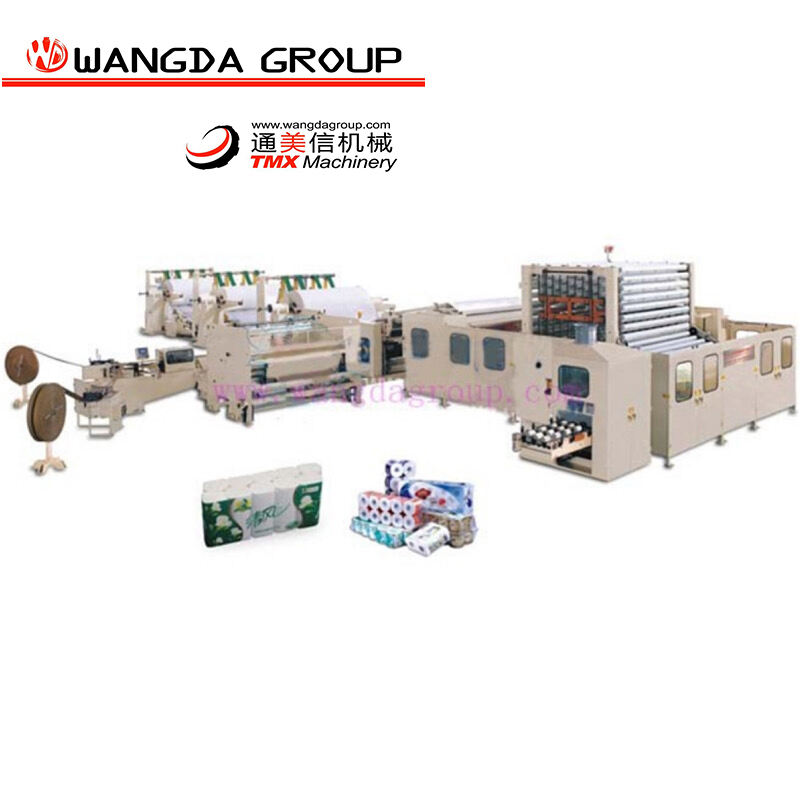

We all use toilet paper on regularly basis. It keeps us clean and healthy after we go to the restroom. It is hard to think this, but will you ever imagine that how the toilet paper are producing? It’s quite interesting! Each bathroom tissue toilet paper is created within a huge factory-like unit in which when this passes through the usage of these equipment, after that what will come over there earlier or later. This large device is one of the devices that produce tissue rolls, then this roll transfers to be cut in smaller size so we take it home and use as individual piece. OK, so what about this special machine beforehand? Let’s find out together

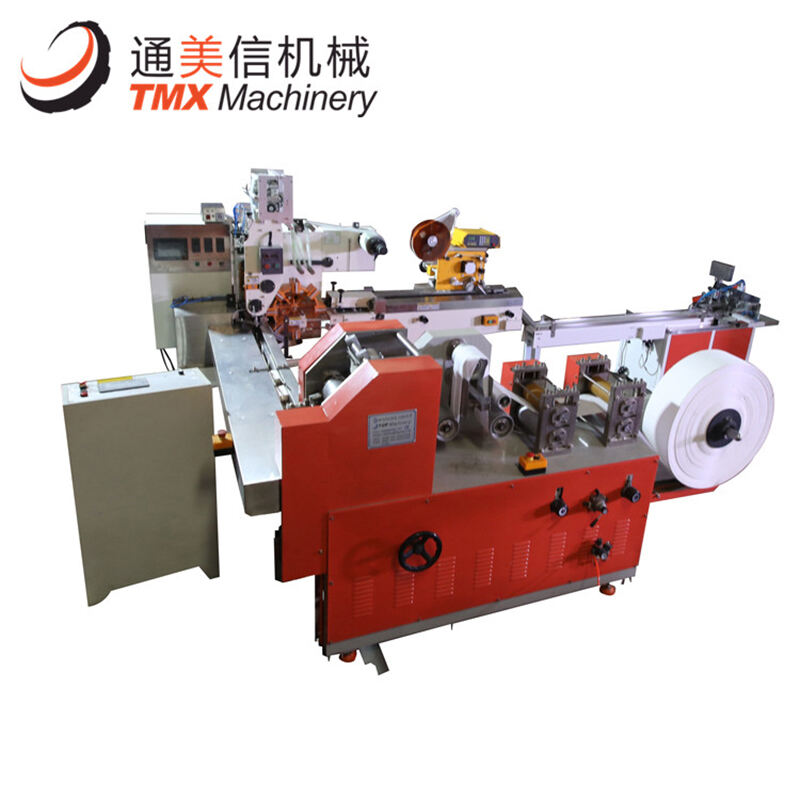

Toilet paper making Wangda Industrial toilet roll making machine cost discussion as follows. Well simply put, toilet paper is made from wood pulp or sometimes recycled papers. Wood pulp — which comes from trees, has many stages before it arrives as a delicate sheet of paper. The pulp is then mixed with water to form a thick liquid known as slurry. A large roller flattens these sheets of the slurry. Then these sheets are dried and rolled into large rolls, which can be further used.