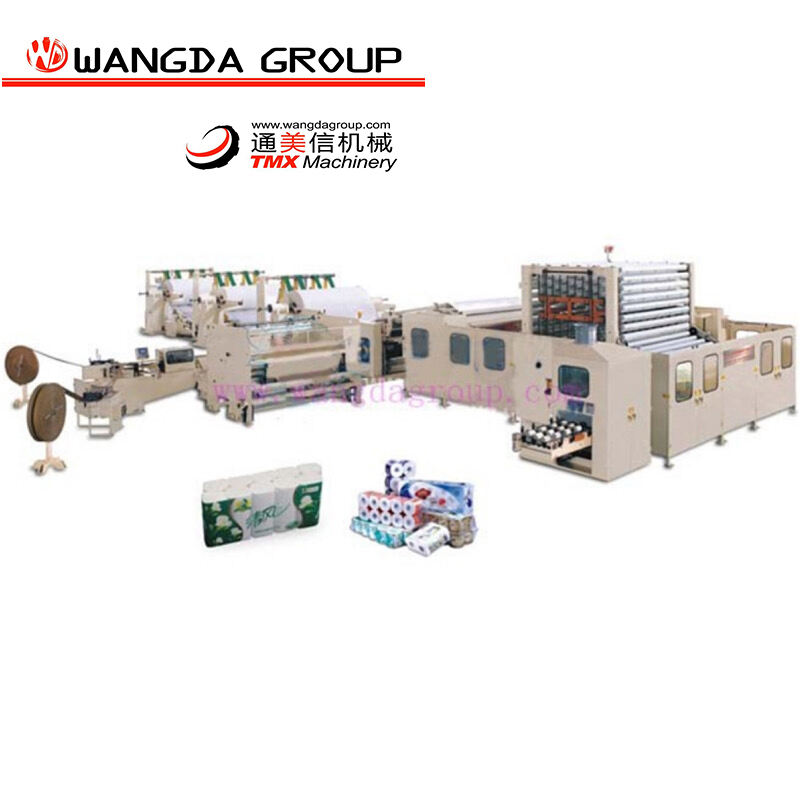

Papier toaletowy jest kluczowym produktem, który pomaga nam być czystymi i свежimi każdego dnia. Czy kiedykolwiek zastanawiałeś się, jak ten miękki, biały papier jest robiony? Pierwszym krokiem jest specjalna maszyna, która ma zdolność do produkcji dużych ilości rol papieru toaletowego w wysokiej prędkości. To dlatego, że mimo że żartujemy sobie z papieru toaletowego, nadal odgrywa on istotną rolę w codziennym życiu. Spróbujmy więc bliżej się przyjrzeć, jak jest robiony i dlaczego?

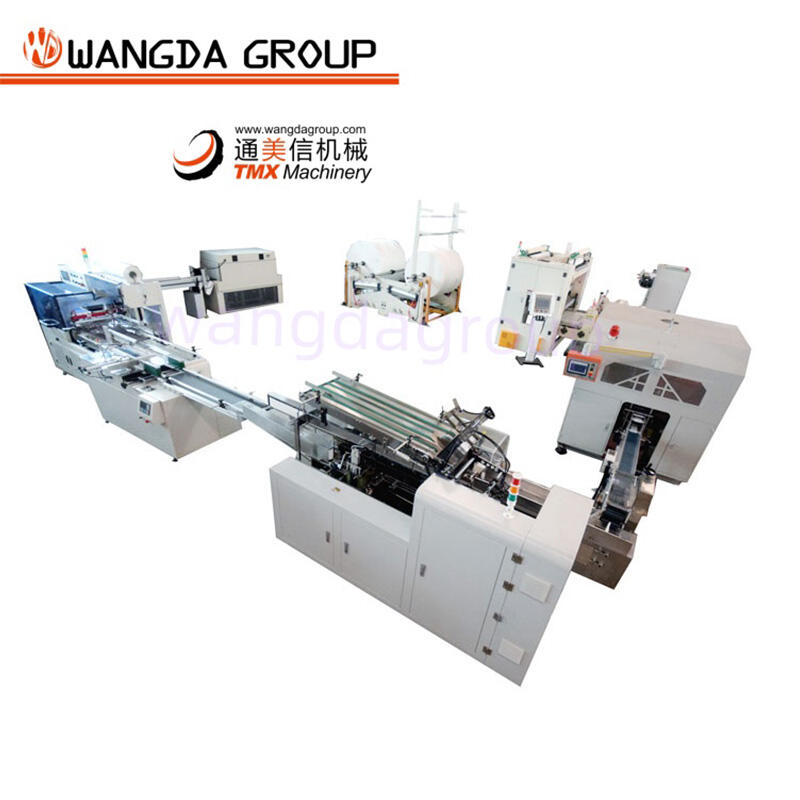

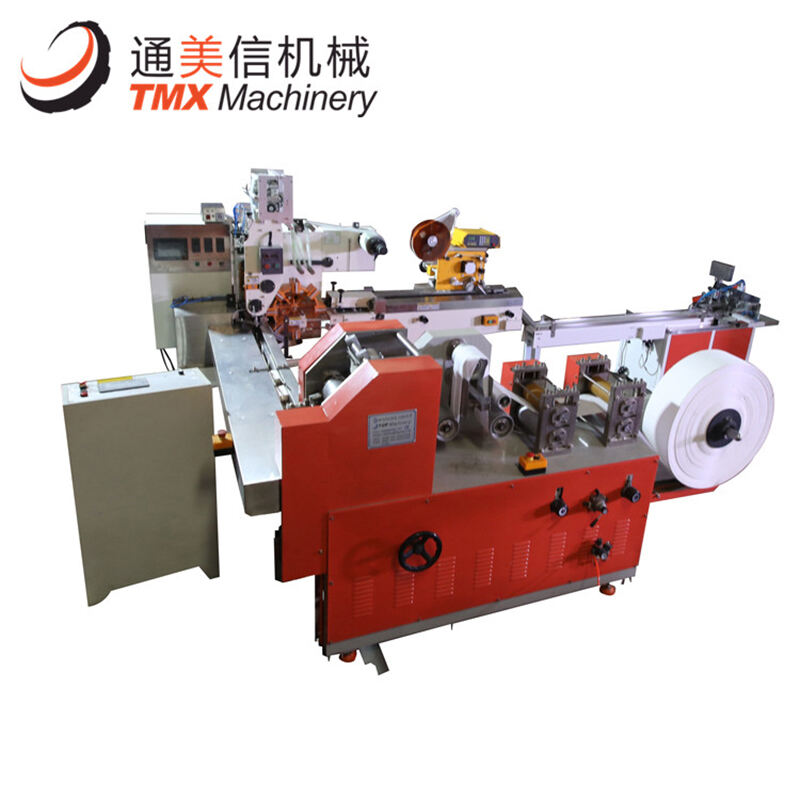

Produkcja papieru toaletowego nie jest łatwa i wymaga również wielu specjalnych maszyn do prania, takich samych jak te z Wangda Industrial wsadowa automatyczna maszyna do składania papierowych chusteczek . Zespoły pracowników produkujących papier toaletowy wybierają materiały, które chcą użyć. Rozpuszczalnikiem jest zazwyczaj celuloza drzewna z drzew, recyklingowany papier lub mieszanina obu plus woda i niektóre chemikalia, które mają w tym pomóc. Pulper: Duża maszyna, gdzie celuloza drzewna lub recyklingowany papier są mieszane razem. Wszystko to trafia do pulpera, gdzie jest mielone, mieszane z wodą i przekształcane w miazgę nazywaną papierową masą.