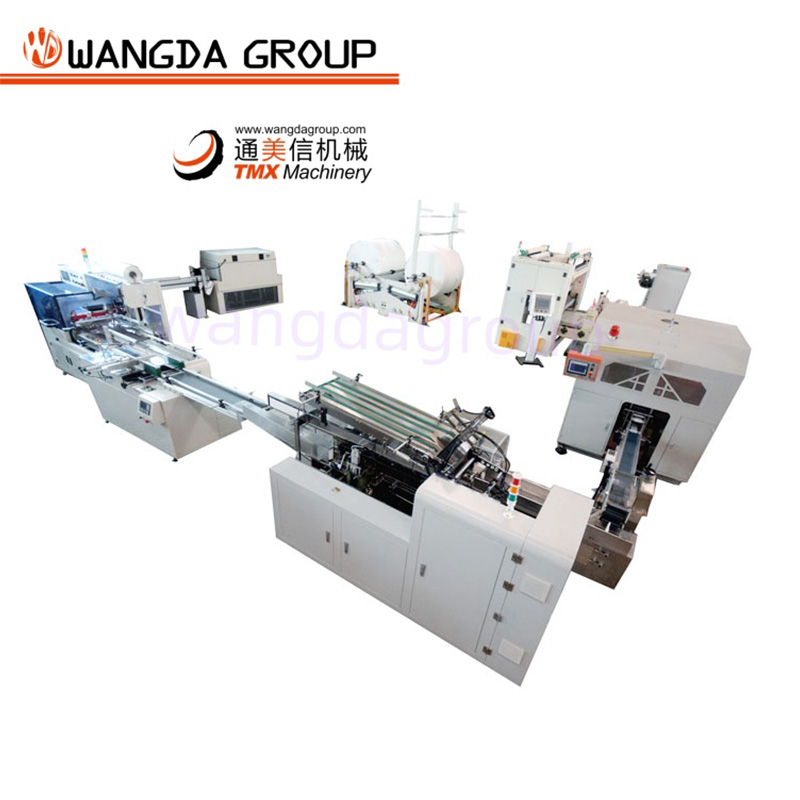

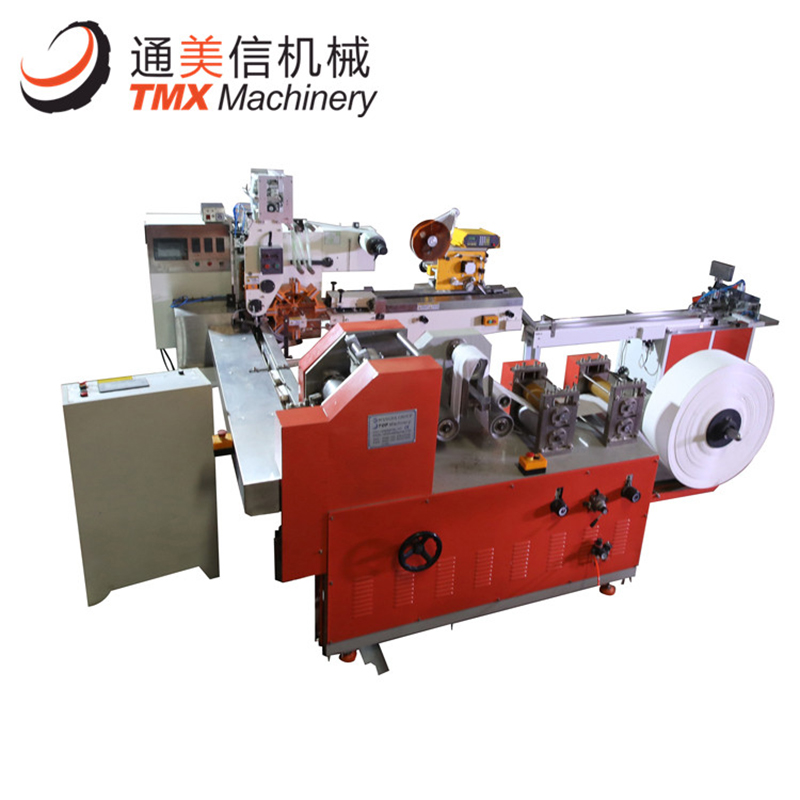

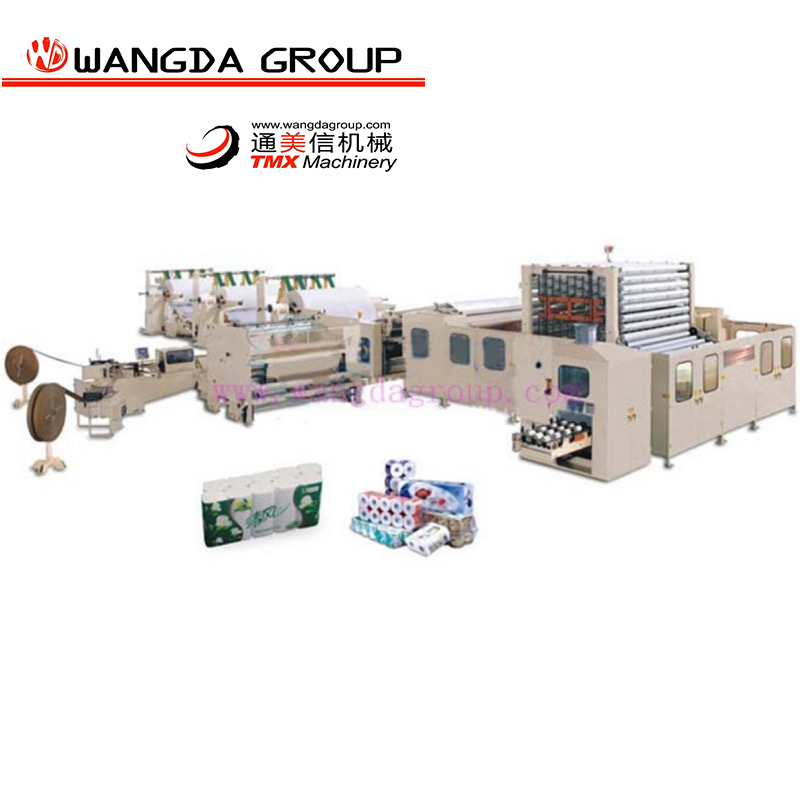

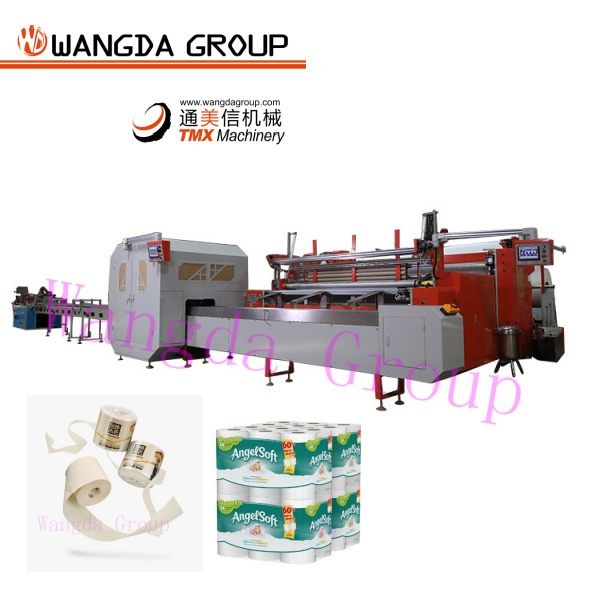

Możemy dostarczyć wszystkie rodzaje maszyn do produkcji papieru ręcznego oraz powiązanych maszyn pakujących i surowców dla całego projektu klucz pod klucz.

Firma Wangda produkuje maszyny do produkcji papieru toaletowego oraz maszyny do cięcia papieru toaletowego, maszyny do pakowania papieru toaletowego, maszyny do cięcia ręczników kuchennych, maszyny do pakowania ręczników kuchennych, maszyny do produkcji papieru higienicznego, maszyny do cięcia papieru higienicznego (do twarzy), maszyny do pakowania papieru higienicznego (do twarzy), maszyny do formowania pudełek na papier higieniczny (do twarzy), maszyny do pakowania papieru higienicznego (do twarzy) w workach nylonowych, maszyny do nawijania dużych rolek (maxi roll), maszyny do produkcji serwetek papierowych, maszyny do produkcji serwetek, maszyny do pakowania serwetek papierowych, maszyny do produkcji małych paczek z papierem higienicznym (do twarzy), maszyny do pakowania małych paczek z papierem higienicznym (do twarzy), maszyny do składania mokrych chusteczek oraz maszyny do ich pakowania – lista ta nie kończy się na tym. Dostarczamy również wszystkie materiały związane z produkcją tych wyrobów higienicznych.