فوائد آلة نواة ورق المرحاض

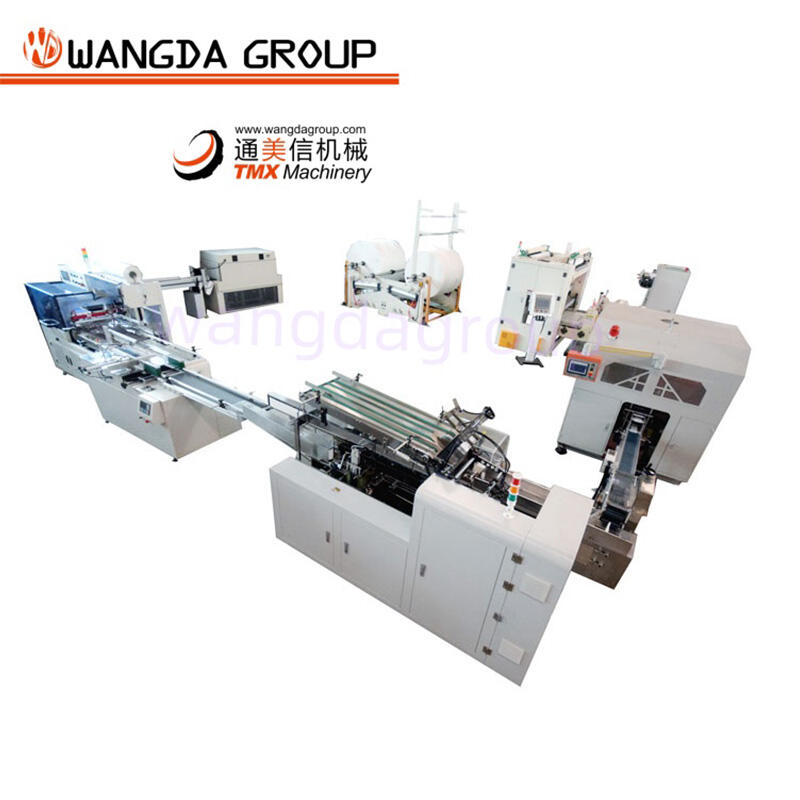

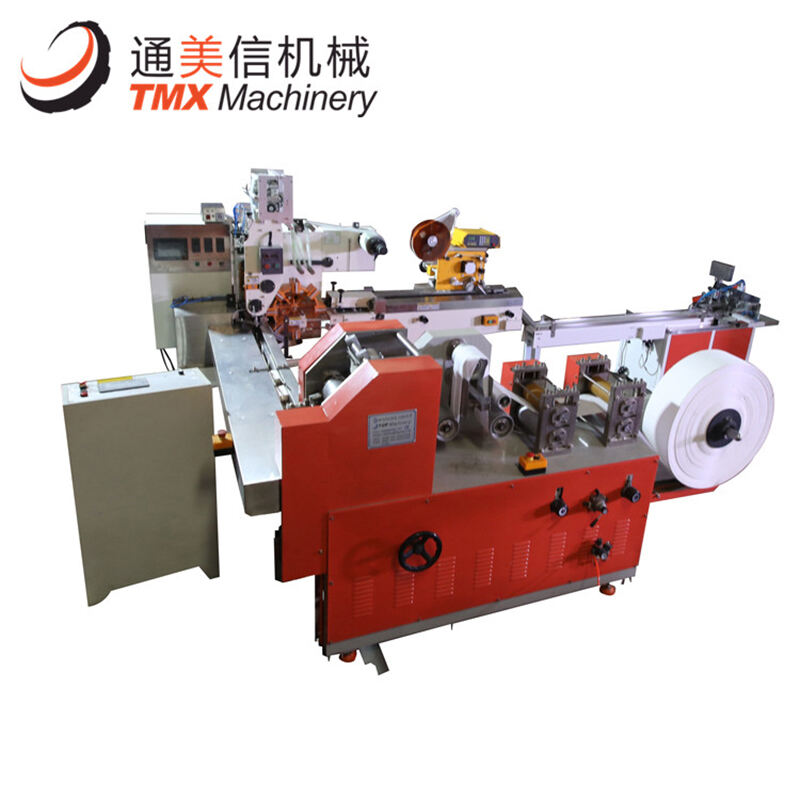

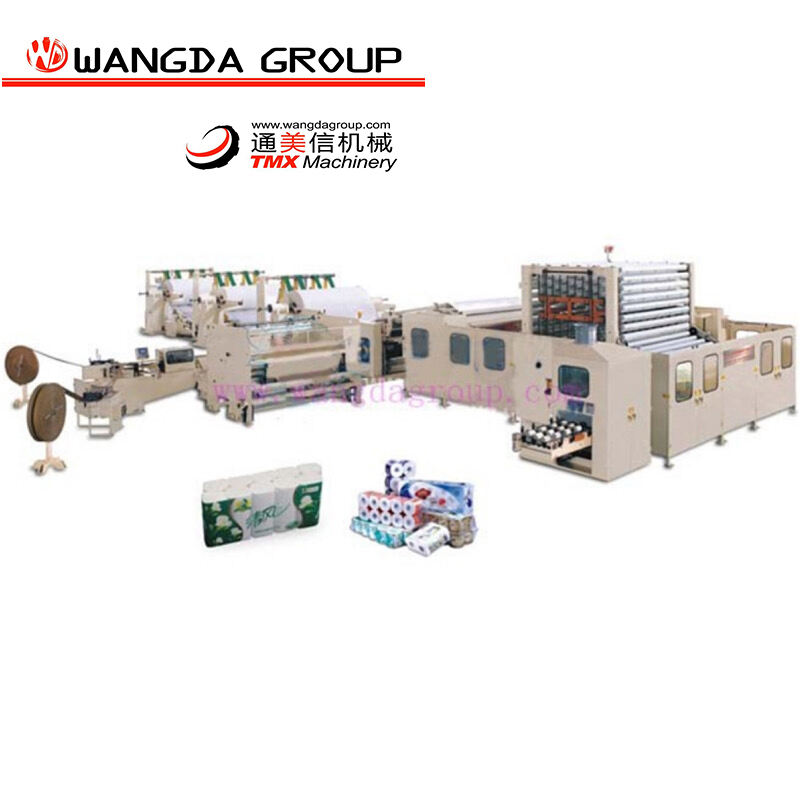

ولكن اليوم، وبمساعدة الآلات الخاصة، أصبح إنتاج هذه الأنابيب أسرع وأسهل. يمكن للآلة إنتاج آلاف الأنابيب الكرتونية في غضون ساعات قليلة، والصفوف المليئة بنواة ورق المرحاض تبدو مثيرة للاهتمام حقًا. هذا التغيير الكبير قد غير طريقة تصنيع ورق المرحاض وجعل كل شيء أكثر كفاءة

لدى آلة نواة ورق المرحاض العديد من الفوائد. فهي توفر الوقت والمال على شركات تصنيع ورق المرحاض. حيث كان العمال سابقًا بحاجة إلى صنع جميع الأنابيب يدويًا، تقوم هذه الآلة بذلك لهم. مما يسمح بإنتاج أسرع لورق المرحاض، ومع ذلك أقل أخطاء، وهو أمر جيد.