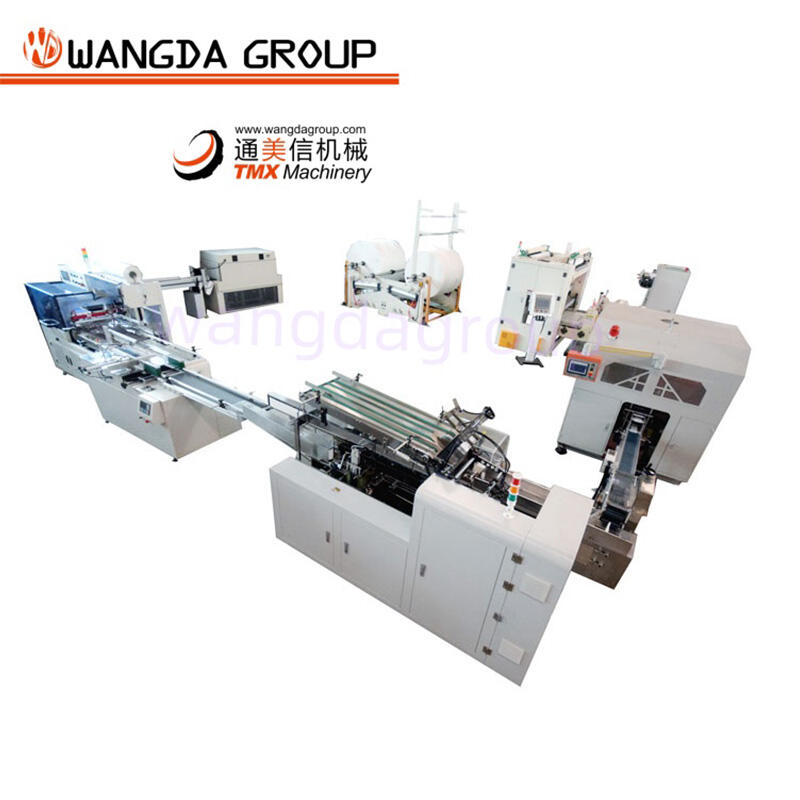

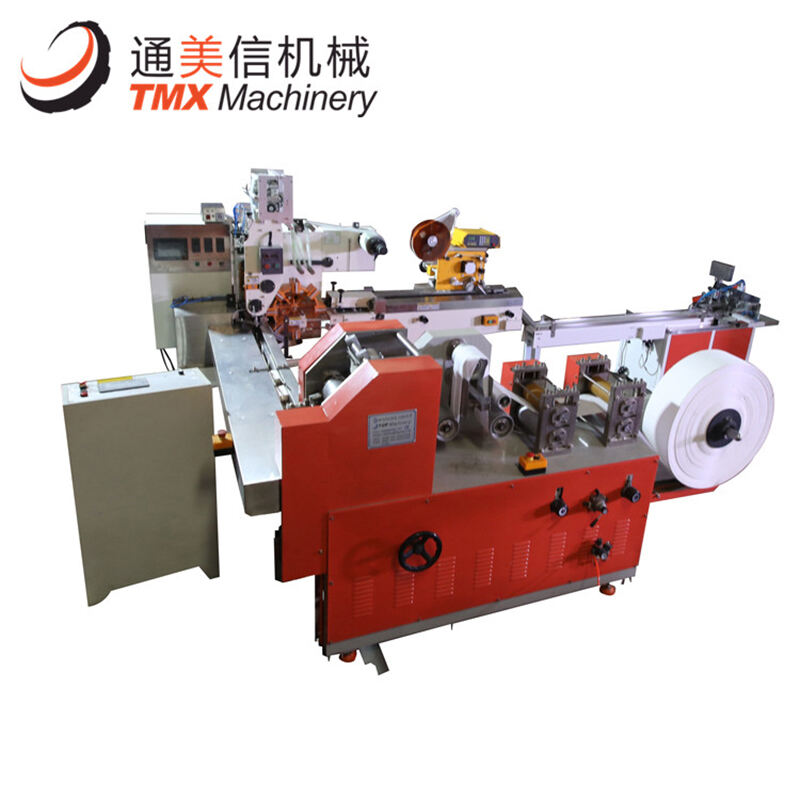

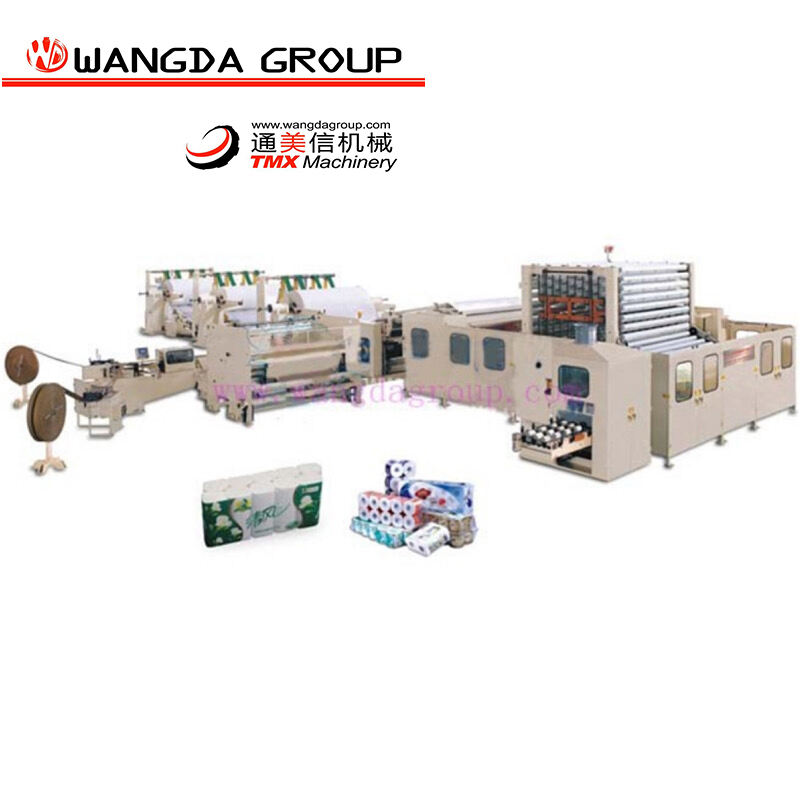

آلة لف الأنسجة هي جهاز ميكانيكي كامل تم تطويره بحيث يبدو وكأنه يولد لفات الأنسجة. كما أن أجهزة التغليف الأفقية تستخدم أيضًا حزمتين كبيرتين مربوطتين كلفات أنسجة، والتي يأخذها الكثير من الناس كأمر مسلم به يوميًا على هذه الأجهزة عالية السرعة. في هذا المنشور، سنقدم لك ما هي آلة لف الأنسجة وآلية عمل خط إنتاج فعال ذو جودة لقطع لفات الورق الكبيرة إلى أحجام أصغر لإنتاج الأنسجة؛ وكذلك لماذا يكون امتلاك واحدة منها مربحًا في المصانع التي تنتج الأنسجة.

العالم يستخدم لفات الأنسجة، بالإضافة إلى منتج شركة وانغدا الصناعية آلة صنع ورق التواليت الصغيرة . نحن نستخدم ورق الأنسجة لأمور عديدة مثل تنظيف أنوفنا عندما نكون مصابين بالزكام أو العطس، ومopping السوائل المتساقطة على الأرض وأحيانًا كورق تواليت. ليس من المستغرب أن معظم الناس يحتاجون إلى الأنسجة والطلب عليها كبير. تقوم هذه الآلات بتصنيع لفات الأنسجة بسرعة هائلة بحيث لا تنفد عند الحاجة إليها لاستخدامات يومية متنوعة.