التكنولوجيا وراء تصنيع ورق الأنسجة

شفرات التجريف: تُستخدم هذه الشفرات لصنع ورق النسيج. لا تزيل هذه الشفرات أي ورق من سطح طبل المجفف يانكي، بل تقوم بدلاً من ذلك بتنظيف خفيف للورق لإنشاء ذلك النمط المميز للتجعيد الذي نراه غالبًا على مناديل الحمام والوجه. ولا تنتهي الوظيفة عند هذا النمط فقط؛ فهي مفيدة أيضًا في جعل ورق النسيج أكثر مقاومة ومرونة واستيعابًا، مما يسمح باستخدامه لأغراض مختلفة.

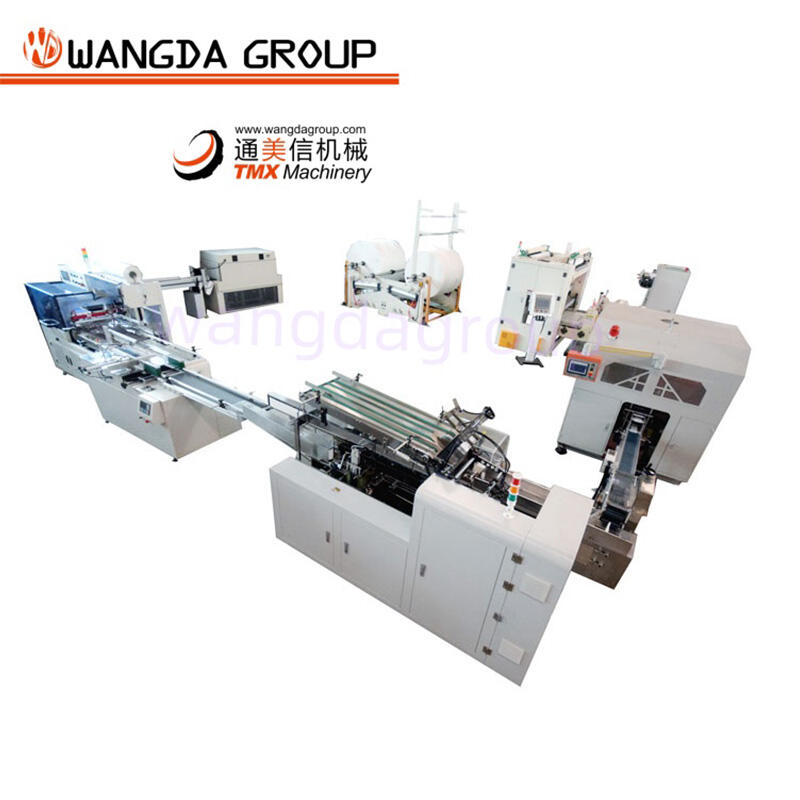

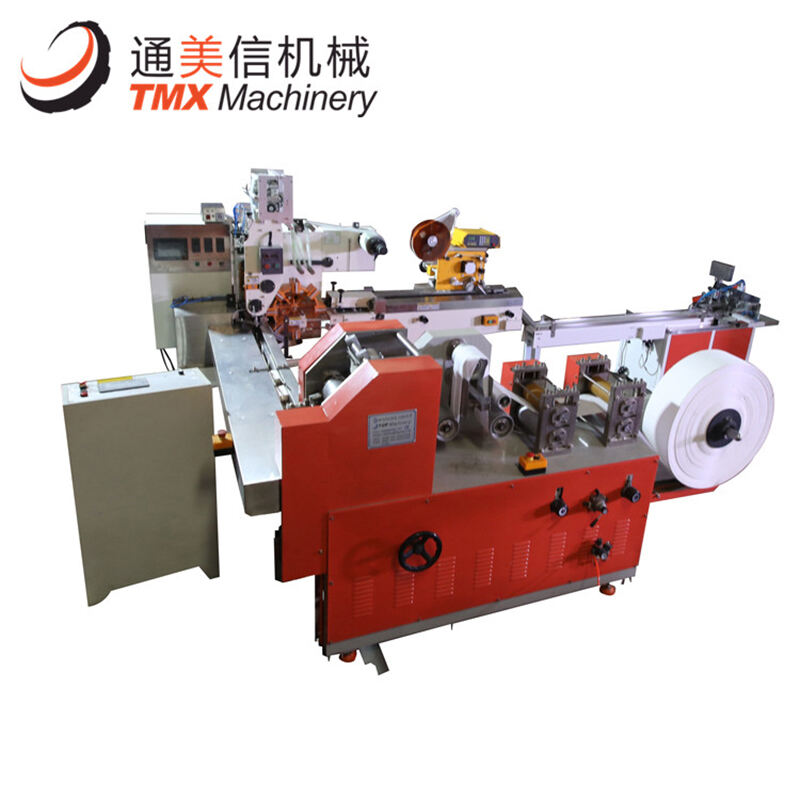

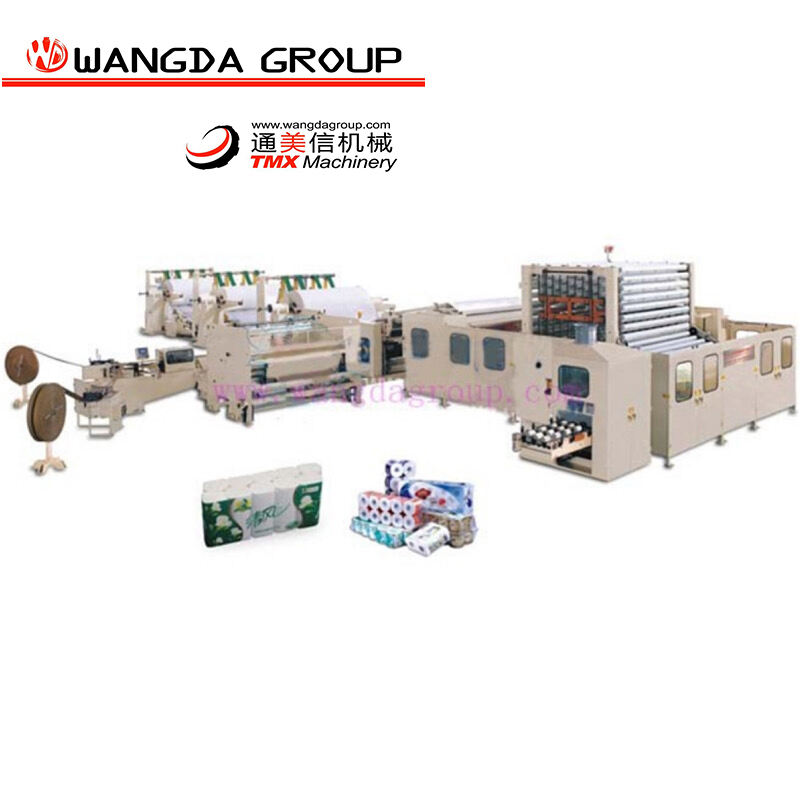

آلة صنع ورق التواليت تعد ضرورية للغاية لعملية خط الإنتاج عندما يتعلق الأمر بإنشاء شيء معين مثل لفة تتعلق بورق الحمام والتنظيف. الآن، ليس من الضروري أن أشرح أنه بدون هذه الآلة كنا جميعًا سنكون عراة لأن هناك لن يكون شيئًا مثل ورق التواليت لنا. كل يوم يستخدم الملايين من الناس ورق التواليت لأغراض مختلفة. من مسح الصدمات إلى النظافة الشخصية، نحن جميعًا نستخدمه بطريقة أو بأخرى، فلماذا لا نختار منتجًا واحدًا من متجر التجزئة ونكون سعداء به؟ لذلك، فإن وجود آلة ستقوم بصنع المنتج بشكل جيد يصبح مهمًا جدًا.