ثورة في تصنيع المناديل

كانت أول آلة لإنتاج المناديل قد ظهرت في الثمانينيات من القرن التاسع عشر. هل يمكنك تصديق ذلك؟ كانت قادرة على إنتاج أكثر من 2,000 منديل في الساعة وتم تشغيلها بالبخار. كان هذا تحسينًا كبيرًا مقارنة بالطرق اليدوية لإنتاج المناديل في الأوقات السابقة. لقد بسطت الأمور بشكل كبير للشركات.

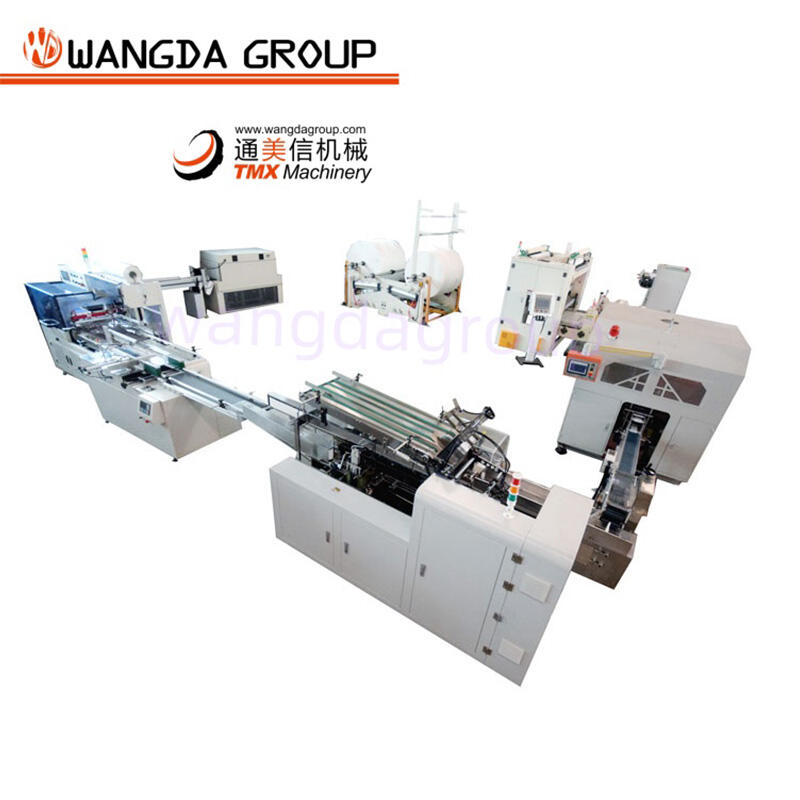

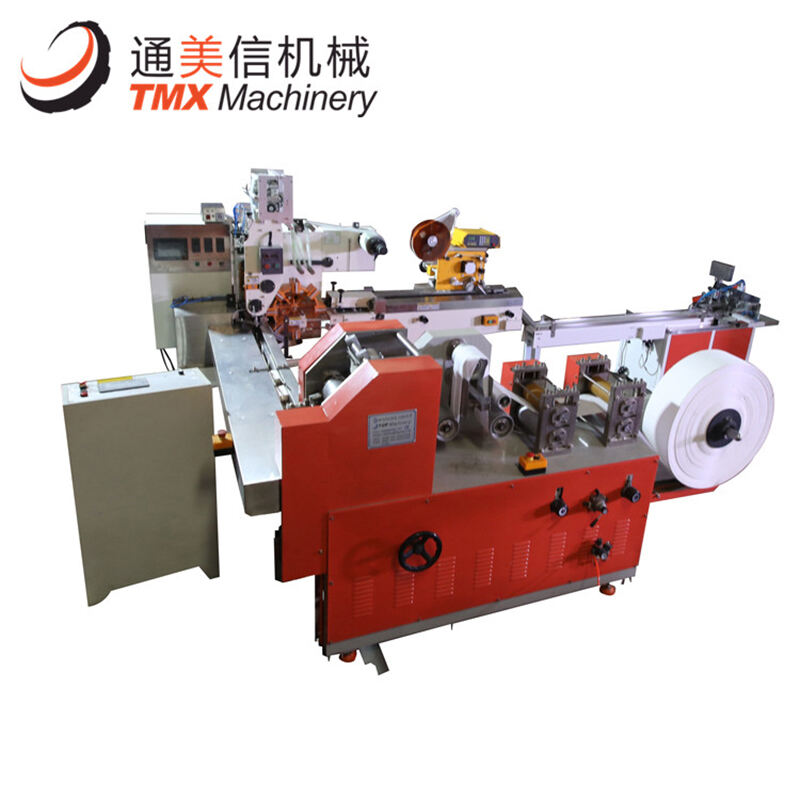

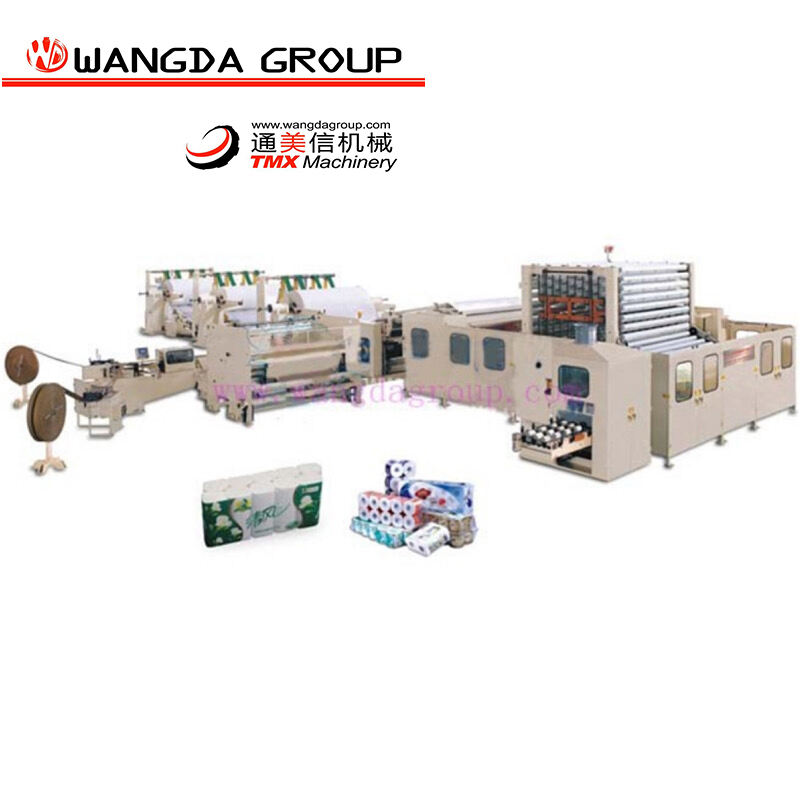

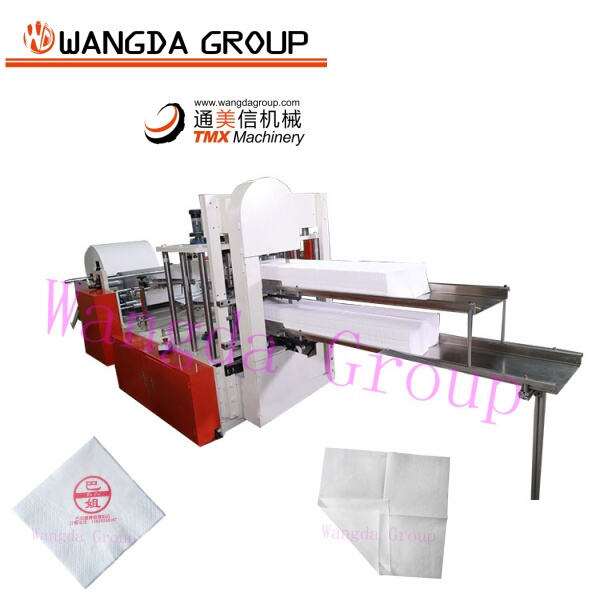

عملية صنع المنديل تتم باستخدام لفة ورق تعمل على إنشاء تلك المناديل الصغيرة، مشابهة لـ آلة المناديل الوجهية الناعمة من شركة وانغدا الصناعية. تبدأ الآلة بأخذ لفة الورق وتقطيعها إلى مناديل فردية. ثم تطوي كل منديل بشكل جميل وتضعها في كومة. إنها مفيدة جدًا في التنظيم، بحيث يمكنني أن يكون لدي كل شيء جاهز للاستخدام.